Thermal Isolation Strip Extrusion Machine

Thermal isolation strip extrusion machine main features:

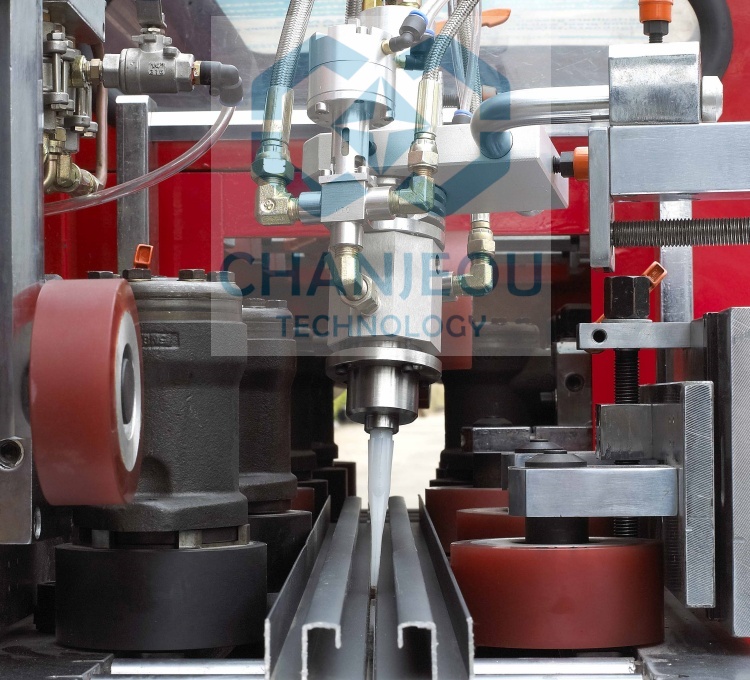

1. Extrude thermal isolation strips smoothly.

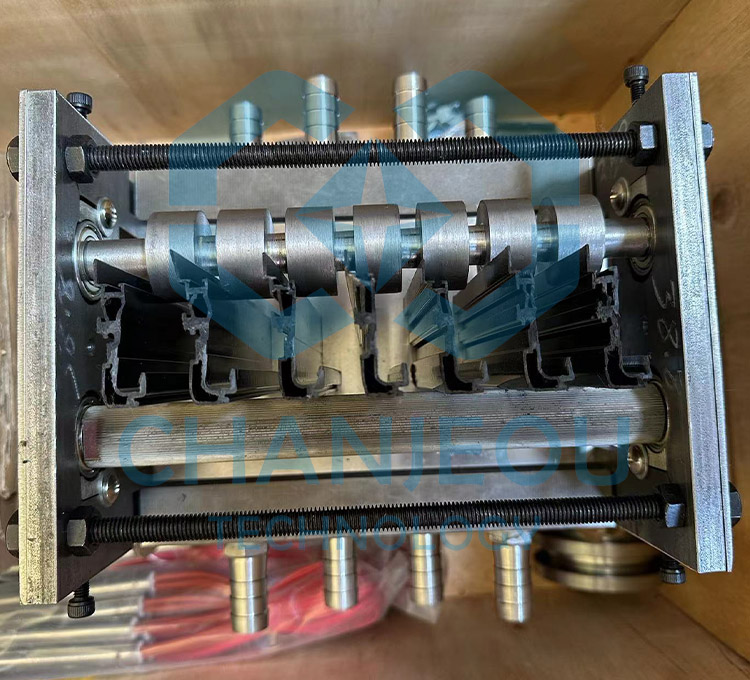

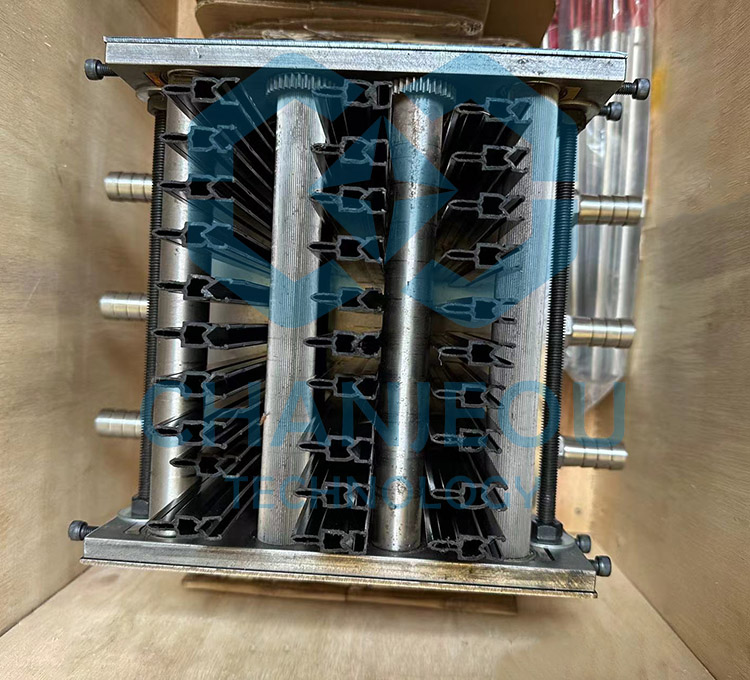

2. Hollow moulds, t shape, ct shape, c shape, i shape, all kinds of strips moulds are available.

3. More than 20 years manufacture experience, widely used all over the china.

4. Export to many countries, including turkey, poland, saudi arabia,germany, canada etc.

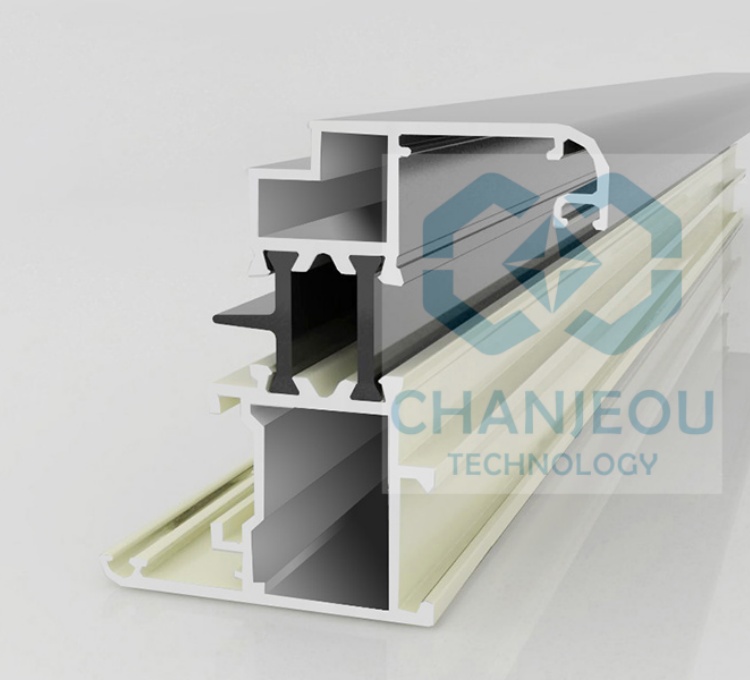

Thermal Isolation Strip Extrusion Machine produce thermal break strips through extrusion moulds by raw material , which is 25% glass fiber, 75% nylon.

Make extruder, extrusion moulds, and thermal isolation strips by ourself, under ourself management, stable quality, extrusion machine run smoothly.

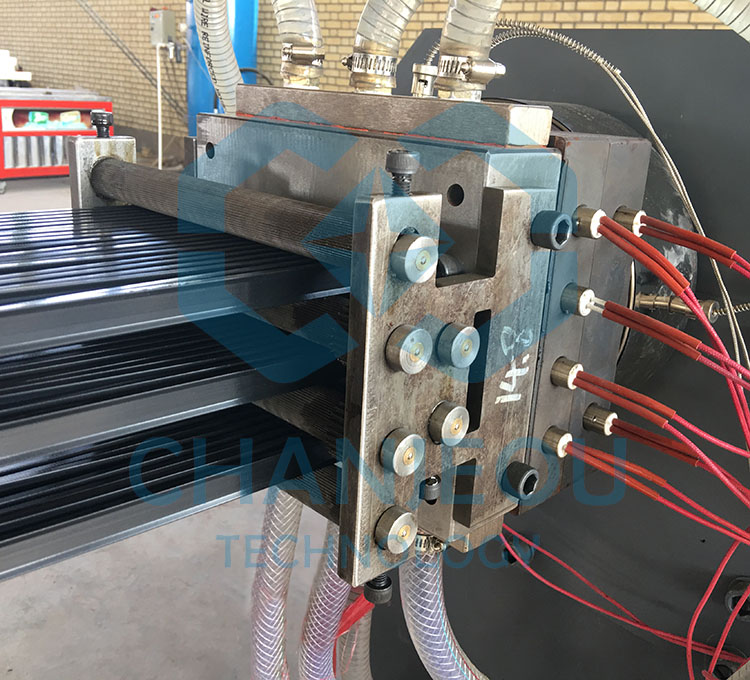

Main Parameters of thermal isolation strips extrusion machine:

1. screw L:D:30:1

2. extrusion mould material: H13

3. extrusion speed: 10~15cm/min

4. strip moulds cavity: 20~120pcs

5. cooling type:water cooling.

6. raw material loading: automatic.

7. strips puller machine: optional.

8. strips cutting: manual or automatic.

9. operator: one person could operate mutiple extrusion machine.

Advantage of finished thermal isolation strips:

1. The glass fiber is evenly distributed.

2. The coefficient of linear expansion is close to that of aluminum profile, and keeps close connection with aluminum profile.

3. Processing temperature as high as 235 degrees, to meet the first to insert the strip after spraying process.

4. size precision is less than 0.05mm

5. With fire resistance, high temperature resistance, chemical resistance, anti-aging, anti-ultraviolet and other functions.