PA66 Thermal Break Strip Extruder

Brand Chanjeou

Product origin China

Delivery time 30days

Supply capacity 200sets/year

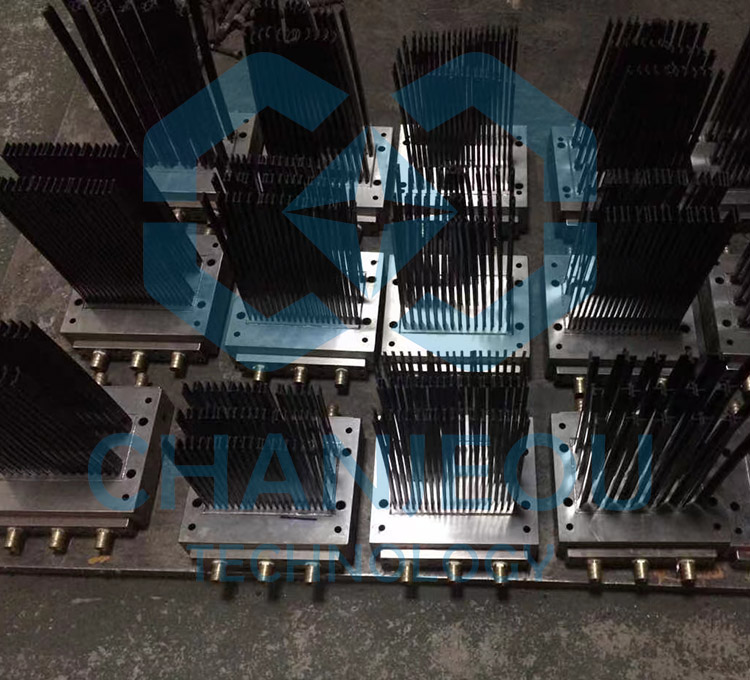

1. All kinds of PA66 strip moulds are available, mature production,fast delivery,steadily working.

2. Widely used all over the world, popular and hot product.

3. one stop solution from PA66 strip raw material, thermal break strip, PA66 strip extruder,Strip moulds, and finished thermal break strips.

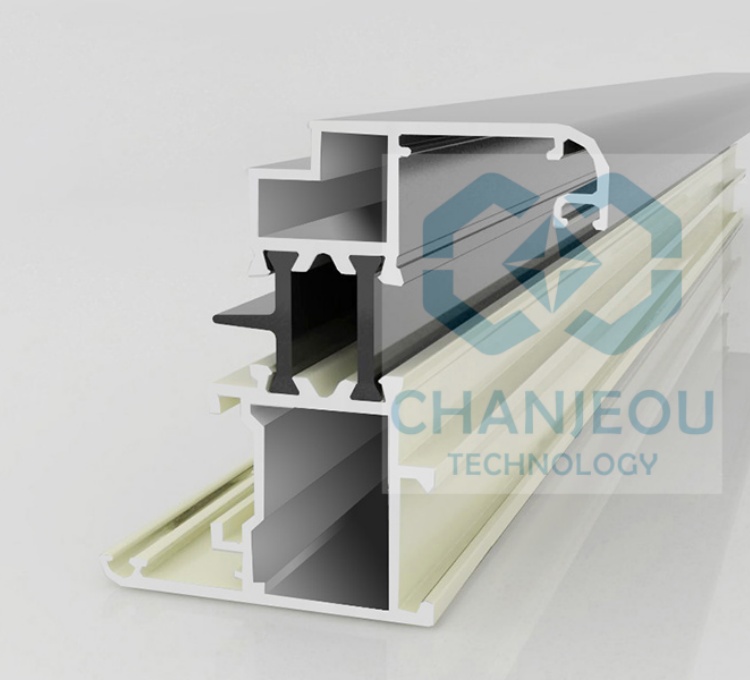

PA66 thermal break strip extruder machine is used for making PA66 strips, which play a part in thermal insulation effect, widely used in aluminum window,door and industry aluminum profile etc.

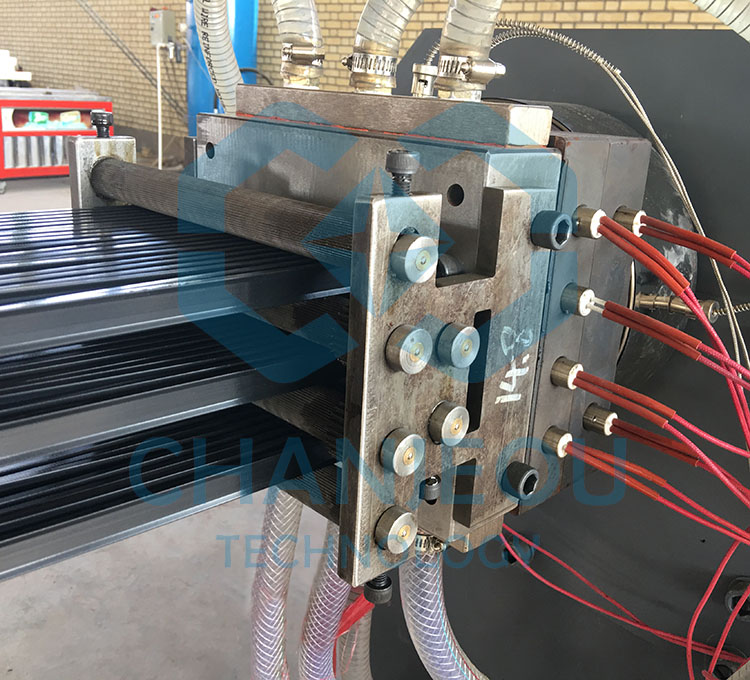

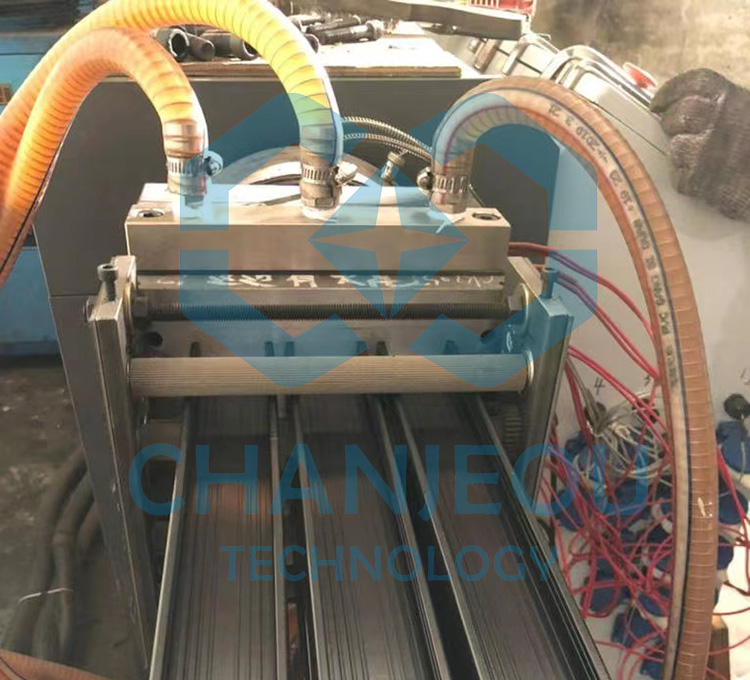

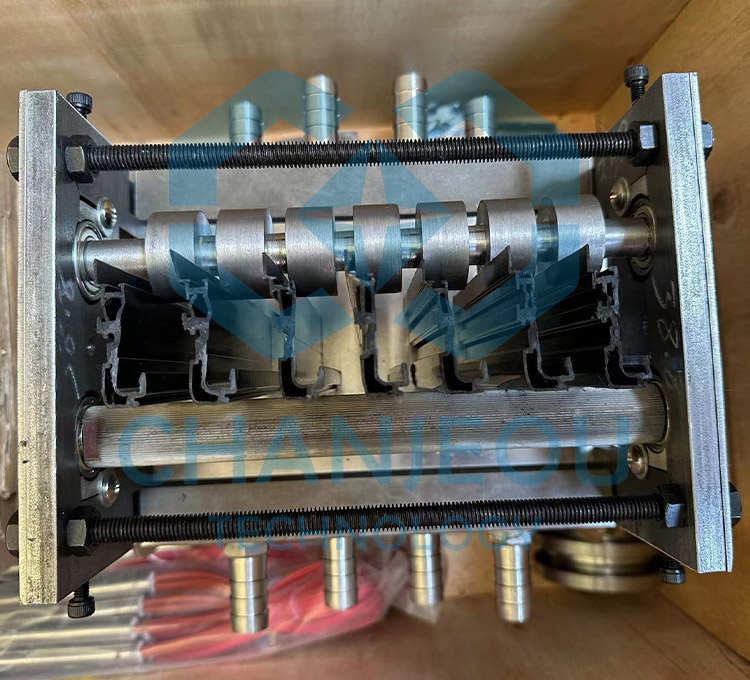

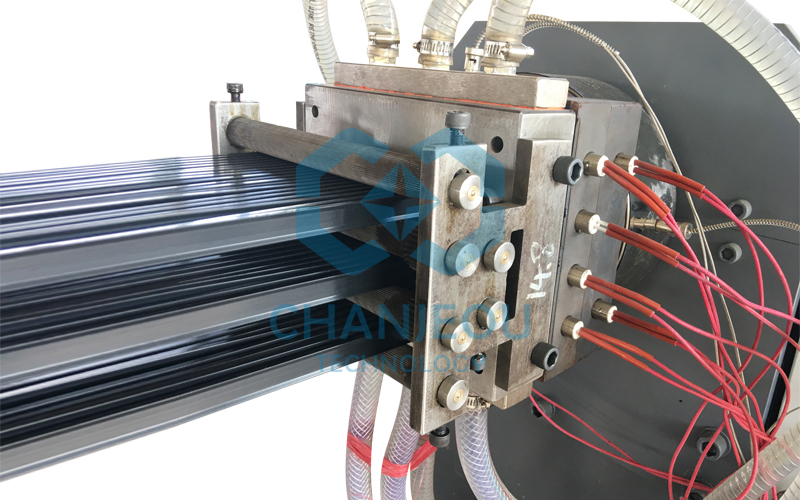

All kinds of thermal break strip moulds are available:

Material list of PA66 extruder machine:

1. Main motor: Siemens,15kw

2. Transducer: Mitsubish,15kw

3. Potentiometer: Omron

4. Temperature controller: Omron

5. Solid state relays: Schneider

6. Intermediate relay: Schneider

7. Mould material: H13

Specifications of Thermal break strip extruder:

1. Total power: 30kw

2. Heating zone: 8

3. L/D: 30:1

4. Precision of mould: less than 0.05mm

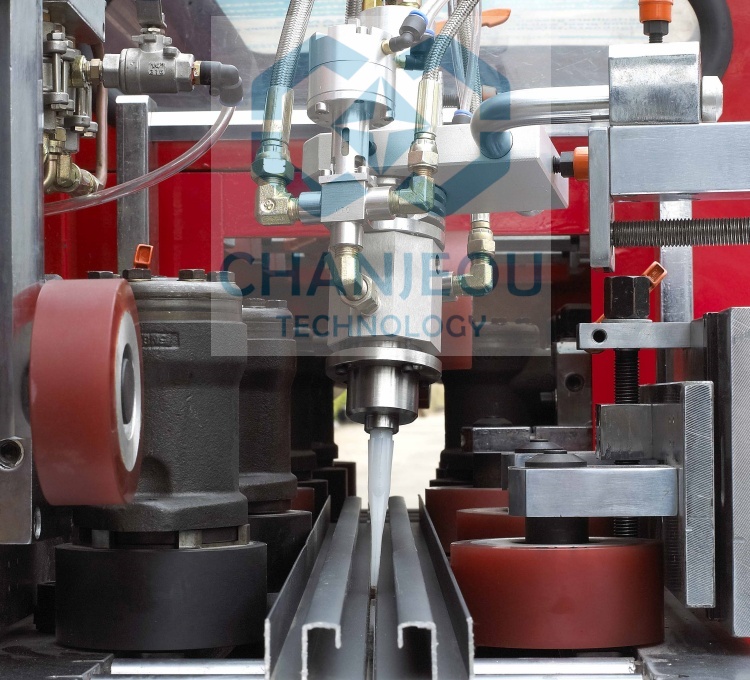

PA66 GF25 thermal break strips extruder machine working procedure:

Raw material (mixture of 25% glass fiber,75% nylon ) is loaded automatically into main extruder machine, through heating and screw, goes into thermal break strips moulds, moulds will be cooled by circulation water, after extrusion moulds, become the product of thermal break strip mouds, the finished strips can be cut as 6m or other length as need, also could be collected by rewinding machine as roll.

During production, the strips cutting machine and strips pulling machine are optional, both of manual cutting and automatic cutting are optional.