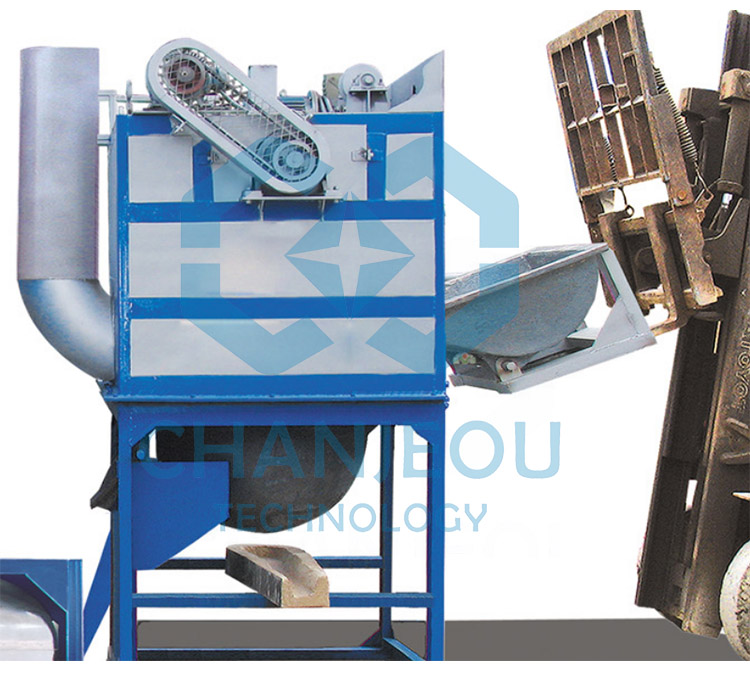

Aluminum Hot Dross Separate Machine

1. When cleaning melting furnace, collect a lot of hot dross, which still include many aluminum, use aluminum hot dross separate machine to recyle aluminum, recycle rate could be more than 85%, recycle agent is de-slag flux.

2. After aluminum hot dross sepate machine, use cooling machine to cool hot dross, milling and screening machine will help to treat remaining dross in further process.

Full line for hot dross treatment machine:

1 aluminum hot dross separate machine: through de-slag flux, 700~750 degree temperature heating dross, aluminum become liquid, collected by pot.

2. remaining hot dross go for cooling machine, after cooling, go for milling and screening machine.

3. milling machine will mill the dross through iron ball, big dross become small.

4. screening machine will separate dross into three kinds of size, small size(40~80mesh),middle size(1.5~3mm),big size(more than 3mm)

small size will be packed

middle size could be as agent for reducing temperature agent during aluminum and dross separate.

big size will go for melting again.

Spare parts for hot dross recycle line:

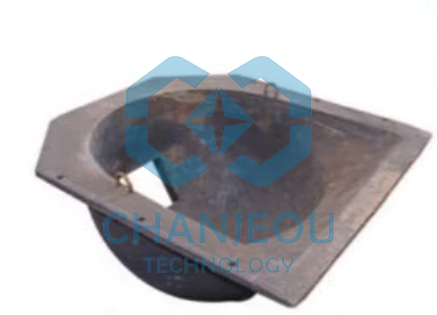

alumin liquid collecting pot:

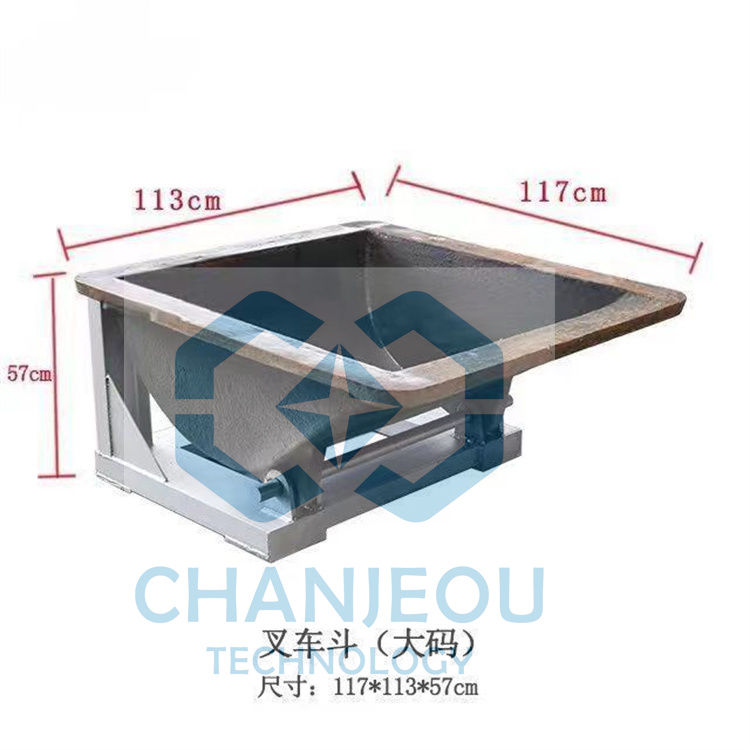

hot dross loading pot:

hot dross mixing stir: