how to compare manual and automatic aluminium profile anodizing plant

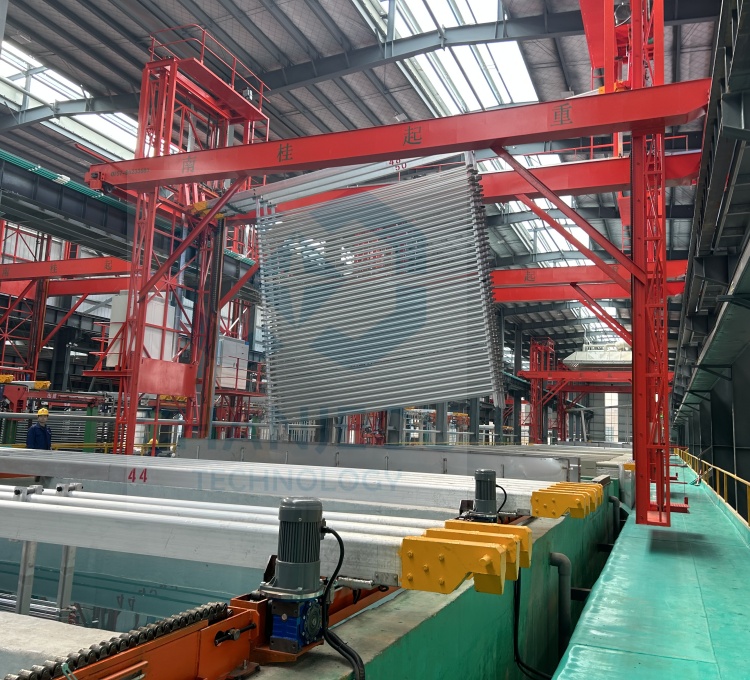

Full automatic aluminium profile anodizing plant mean features:

1,no need labor to operate crane machine

2,no need labor to operate rectifier

3,SCADA show all running situation, only need one labor to operate chemical and monitor the scada.

Semi automatic aluminium profile anodizing plant main features:

1,need labor to operate crane machine, how many labors depend on production capacity

2,when chemical is ready, need labor to operate rectifier

3,HMI will show parameters,but cat now show working photo or video online.

4,on basis of semi automatic line, if make simple crane machine, then become manual anodizing plant.

Which condition choose full automatic aluminium anodizing plant?

1,production capacity is big

2,small item such as hardware anodizing line

Design type of aluminium anodizing plant:

1,U type

2,straight type

Tank material for aluminium profile anodizing plant:

1,PP tanks,

2,Concrete tanks

3, stainless tanks

4,MS tanks

What is difference betwen the hard coat anodizing and regular anodizing process ?

1, hard coat temperature is 0~5 degree, regular anodizing temperature is 18~22 degree

2, hard coat current density is 300A,regular current density is 130A

3,hard coat concentration is around 20%,regular anodizing concentration is less than 15%

4,hard anodizing film thickness is more than 15um,regular anodizing film thickness is 8~15um(depend on product)

5,hard anodizing surface is rough,regular anodizing surface is smooth

6,hard coat sealing coefficient is less ,regular anodizing sealing coefficient is higher.

Which product need hard coat profile anodizing plant?

Hard oxidation is required for wear-resistant parts that require high hardness (such as pistons, cylinders, bearings, rails, etc.), parts that require insulation, parts that are resistant to air flow erosion, and parts that can withstand high temperatures instantly

Project : Bangladesh,India,Jordan etc.

Chanjeou company advantage of aluminium anodizing plant:

1,professional technology support,face to face talking could solve all your doubts in technolocy

2,fast installation ,united team cooperate perfectly

3,honesty sales service

4,top quality with good price

Which information give to us for getting aluminium anodizing plant layout and details offer?

1, product type

2, product maximum length

3,monthly capacity

4,daily working hours

5,monthly working days

6,color requirement

7,anodizing thickness

8,land space or workshop space or layout in autocad

Contact us: