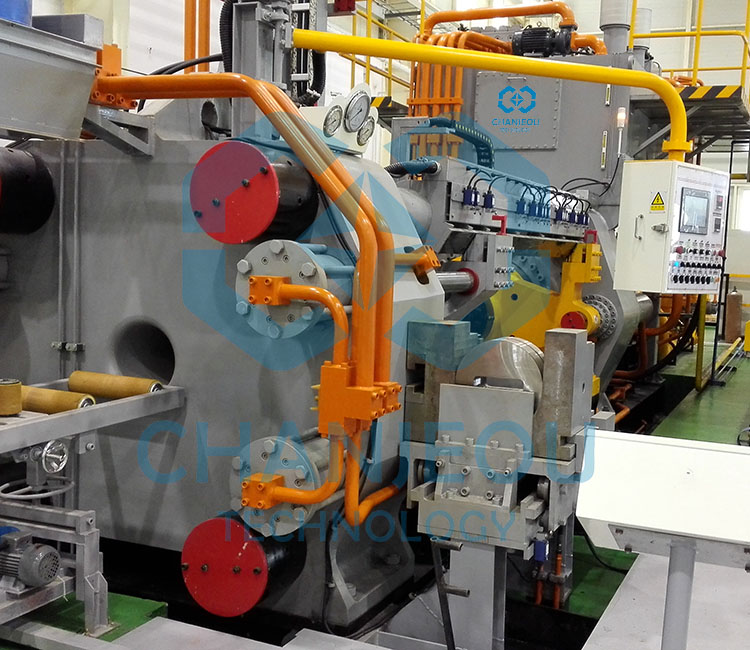

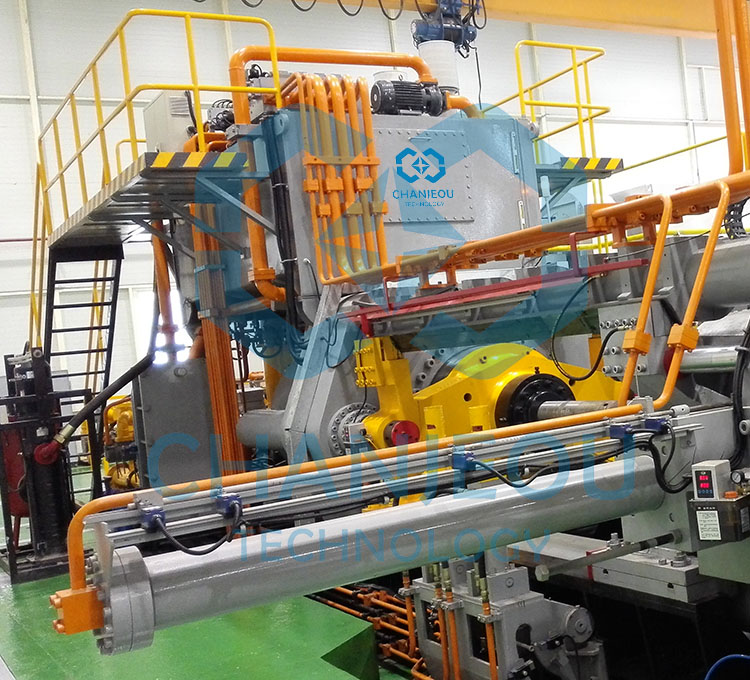

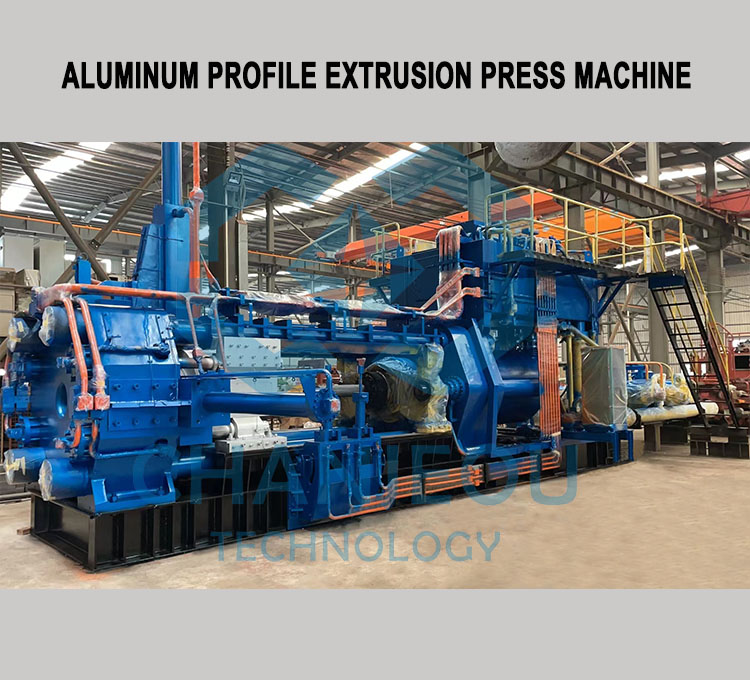

Short Stroke Aluminum Extrusion Press Machine

Brand CHANJEOU

Product origin China

Delivery time 6months

Supply capacity 200sets/year

1. Short stroke extrusion press machine's dead cycle time is shorter, adopt the extrusion stem moving up-down, and manipulator moving horizontally to apply the billet from the back of container.

2. Extrusion press machine have short idle time, from the last billet extruded and open the container to completion of upsetting exhaust of next billet.

3. On basis of short stroke design, aluminum extrusion press machine use frequency converting technology is used for achieving the optimal coordination among pressure, flow and motor speed, which can reach high efficiency on the basis of 15% effective energy saving.

Regular 8inch(2300UST) short stroke design extrusion press machine main parameters :

1. billet diameter: 203mm

2. billet length: 950mm

3. may cylinder capacity: 2300US Ton, 210kgf/cm2

4. regular mould size: dia,400*400mm

5. aluminum profile discharge size: dia,250*330mm

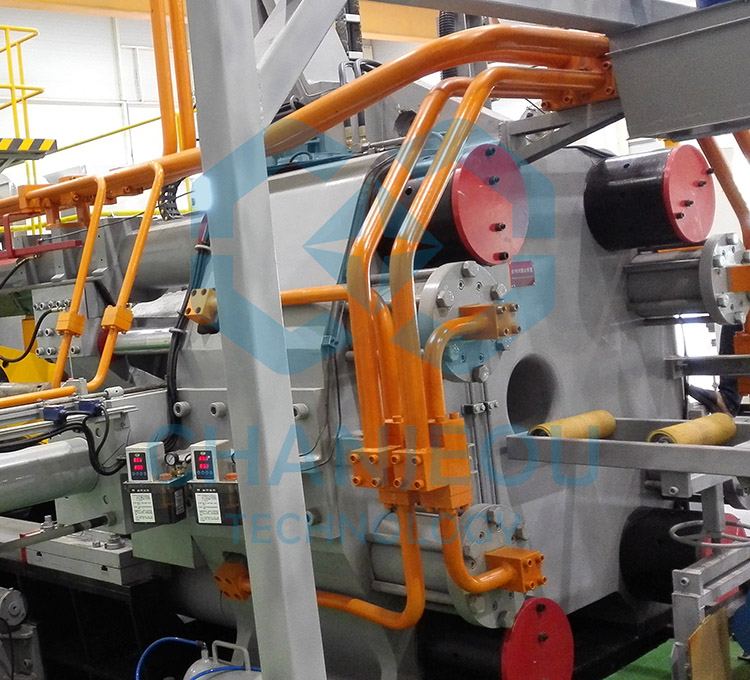

Speed of 8inch aluminum profile extrusion press machine:

1. Extrusion time: 18mm/sec

2. Dead cycle time: 25sec

3. container released time: 132mm/sec

4. container closed time: 160mm/sec

5. shear down: 568mm/sec

6. shear up: 715mm/sec

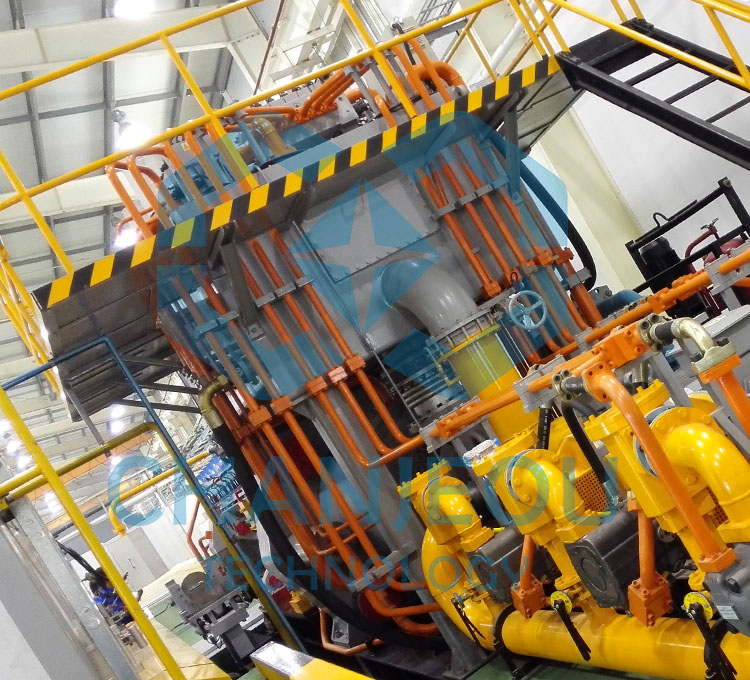

Main material list:

1. Main pump: Germany Rexroth,4pcs

2. high hydraulic valve: Germany Rexroth

3. Touch screen: Porface

4. PLC: Siemens or Mitsubishi

5. Limist switch: Omron

6. Main cylinder: forged

7. main cylinder pistion: alloy cast iron

8. tie rod: 40Cr

9. front platen: 35# cast steel

10. container seat: 35# cast steel

11. Container : 5CrMnMo

12. Container liner; H13

13. Stem :H13

14. Dummy block: H13

15. die slide seat: 35# cast steel

All parameters and design could be customized on basis of aluminum material