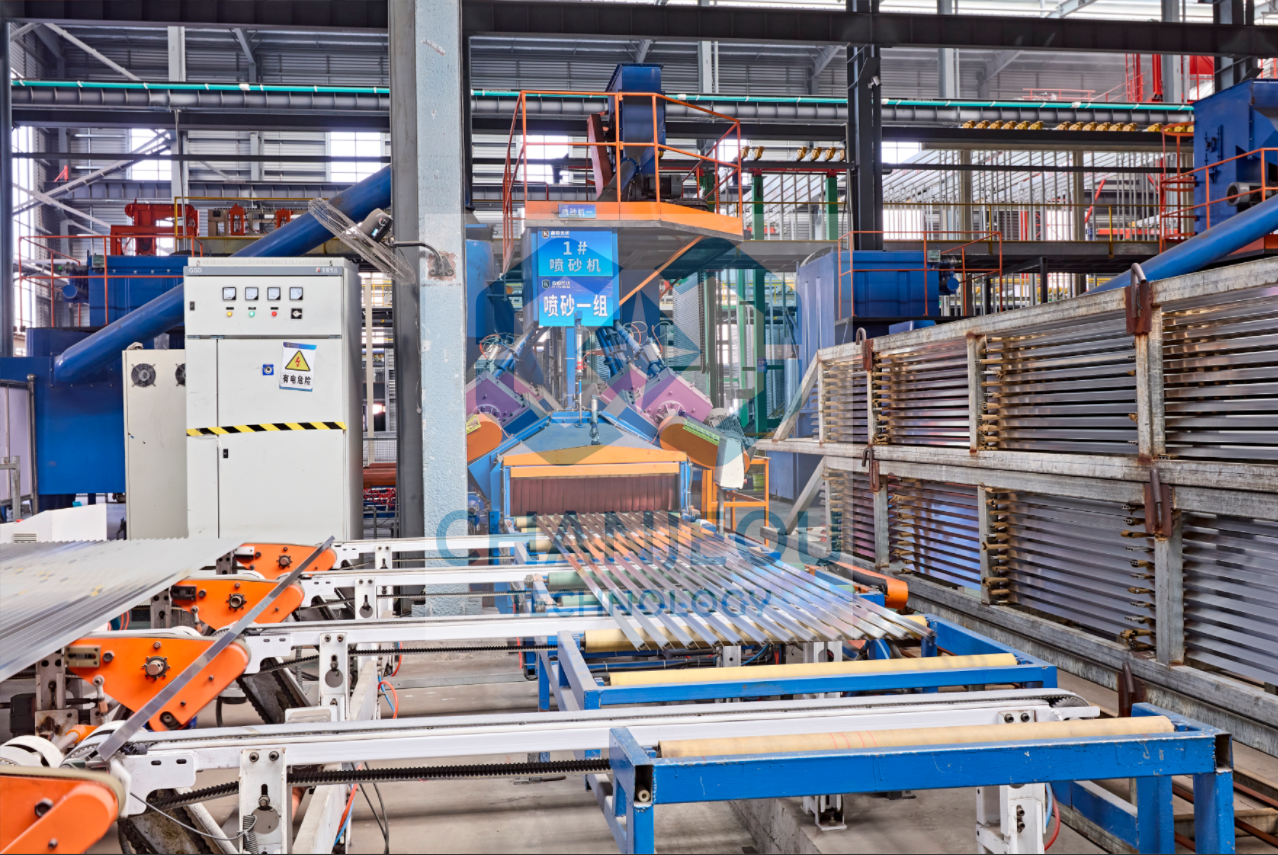

Aluminum Solar Frame Profile Sand Blasting Machine

Top manufacturer of Aluminum solar frame sand blasting machine:

1,fast delivery

2,popular used

3,good price

Sand blasting machine realize full automatic work, also full automatic connect with aluminum anodizing production line.

Raw material of sand blasting machine is stailness sand,how to choose stainless sand?

1, stainless sand size should be suitable

2, stainless sand material should be stainless, not iron

3, stainless sand shape should be round, can not be sharp

Sand blasting machine including:

1,automatic loading table

2,automatic feeding table

3, automatic sand blasting machine

4,automatic sand loading

5,automatic solar frame dishcarge table

6,electrical control cabinet

Design of aluminum solar frame sand blasting machine:

1,4pieces of blasting guns

2,6pieces of blasting guns

3,8pieces of blasting guns

Which design is best for sand blasting machine?

4pieces of guns aluminum solar frame blasting machine is suitable for very small production capacity

normally do not sugget 6 pieces of blasting machine

if production capacity is not small, good choice is 8piece of aluminum solar frame sand blasting machine

Why alunimum solar frame need sand blasting effect?

1,Removing surface dirt and defects by aluminum solar frame sand blasting machine : During the production and processing of solar aluminum materials, the surface may be contaminated with dirt such as dust and oil, which can affect the adhesion of subsequent surface treatments such as spraying and electroplating. Sandblasting treatment can effectively remove dirt and pollutants by high-speed spraying of abrasive particles, restoring surface cleanliness

2,Increasing surface roughness by aluminum frame solar frame sand blasting machine: If the surface of aluminum is too smooth, it will affect the adhesion of the coating or plating, which can easily lead to peeling or flaking. Sandblasting treatment can form tiny bumps and depressions on the surface of aluminum, increase surface roughness, thereby improving the adhesion of coatings or plating layers and ensuring their firm adhesion to the aluminum surface

3,Removing anodizing layer by aluminum solar frame sand blasting machine: Aluminum is an active metal that easily reacts with oxygen in the air to form an oxide layer. Although this oxide layer has a certain protective effect on aluminum, it may affect its aesthetics and performance in certain application scenarios. Sandblasting treatment can remove the oxide layer through the impact force of abrasive particles, exposing fresh metal substrates and improving the adhesion with coatings or plating layers

4,Improving anti-corrosion ability by aluminum solar frame sand blasting machine: Sandblasting treatment can not only remove surface dirt and oxide layers, but also increase surface roughness, thereby enhancing the anti-corrosion ability of aluminum materials. Processed aluminum can be used in harsh outdoor environments for 25-30 years without any problem

Improving appearance quality: Sandblasting treatment can remove defects such as scratches and dents on the surface of aluminum materials, making the surface smoother and more even. At the same time, different textures and patterns can be formed according to needs to meet customers' personalized needs

Contact us:

Email:melody@chanjeou.com

Whats app:0086 13450531604