PU polyurethane potting machine for thermal insulation aluminum profile

PU polyurethane potting machine for thermal insulation aluminum profile:

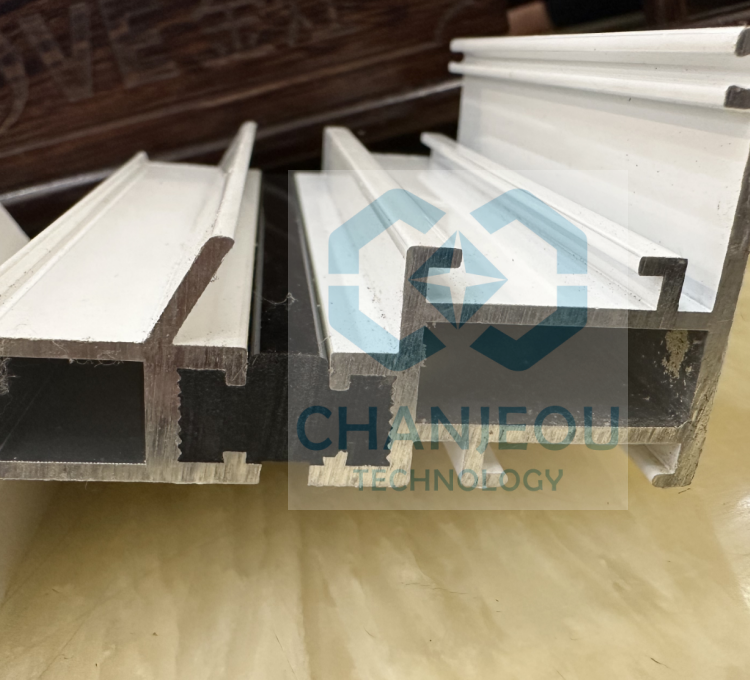

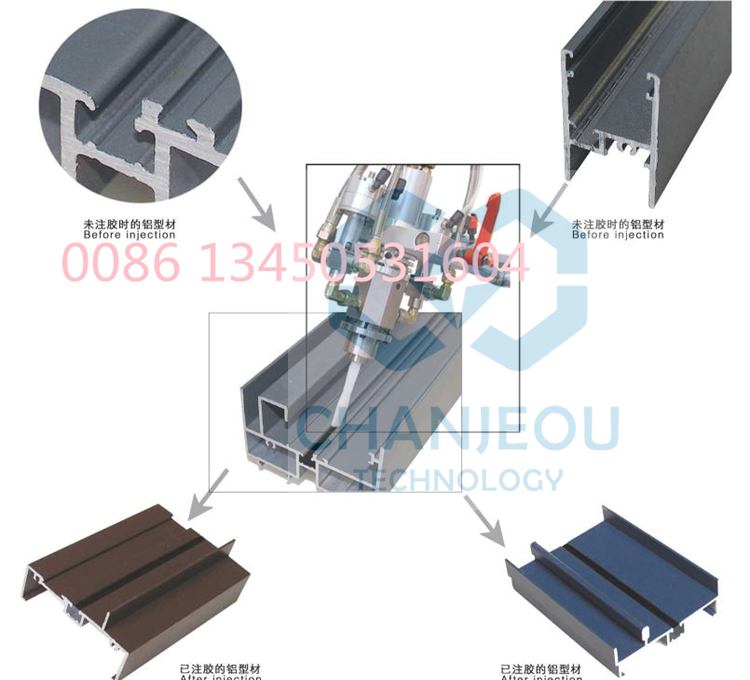

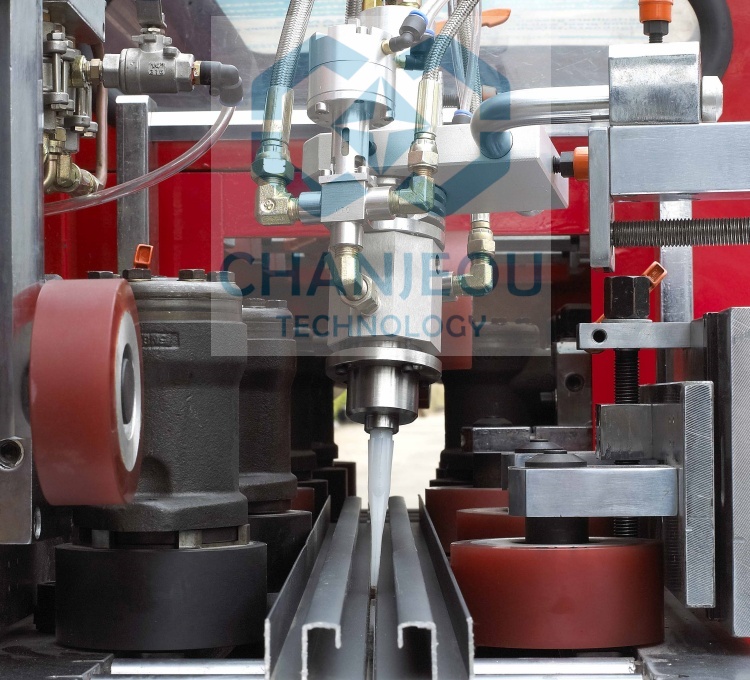

Potting PU polyurethane in slot of aluminum profiles, thermal insulation function.

PU polyurethane potting machine for thermal insulation aluminum profile including:

1, teeth knurling machine in slot of aluminum profile, increase strength of thermal insulation

2, potting PU in slot of teeth made position of aluminum profiles

3,cutting the metal connecting parts which has been potting PU.

Polyurethane advantage:

1,before A and B mixing, it is liquid

2,after potting A and B PU, fast become solid within 25seconds.

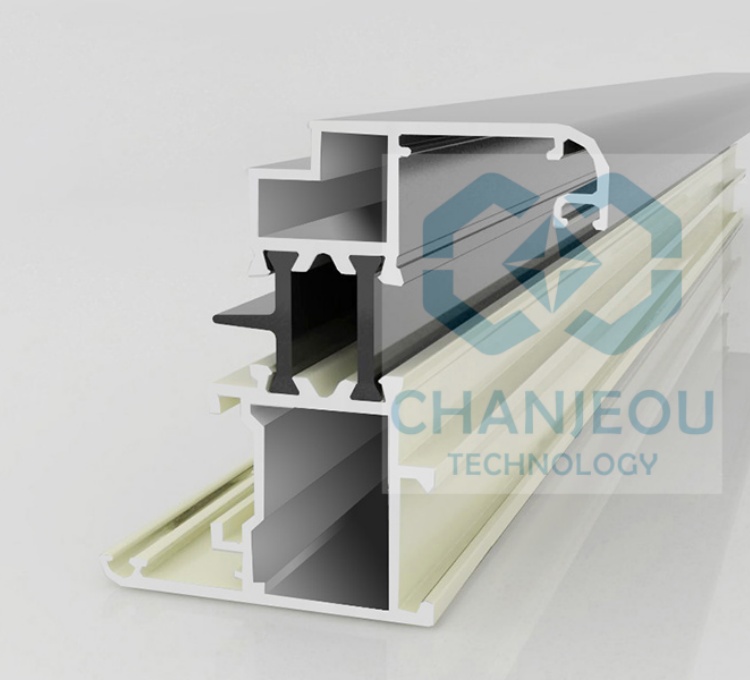

3,polyurethane have low thermal conductivity, let metal connect by polyurethane, play a part in thermal insulation function, called thermal insulation aluminum machine.

Two kinds of thermal insulation machine:

1,polyamide strip type:

price is cheaper

can do different color

many kinds of different design

popular in Asia country

2,polyurethane type

better sealing, better water-proof function

price is higher

popular in America and European country

Knurling machine is first step of PU potting machine machine for making thermal insulation aluminum profile, use the knurling knife to make teeth in slot of aluminum profile, let aluminum bite the PU tightly.

Main parameters of thermal insulation polyurethane potting machine:

| maximum profile width | 250mm |

| maximum profile height | 200mm |

| teeth distance | 2~9.5mm |

| teeth making speed | 0~60m/min |

| conveyor table length | 5.5m |

| machine need floor size | Length 13.8m*width 8.8m, height 2m |

Design advantage of PU potting machine:

1.1.1、Polyurethane injection machine three sets of hydraulic system, including mixer, aluminum profile feeding, glue feeding, product steadily, each set has each motor &oil pump).

1.1.2 、 Hydraulic station has two sets of air cooling device(cooling for hydraulic oil cooler).

1.1.3、Supporting plate use imported precision linear guiding rail, make it flexible, when handle supporting plate, will not bend profile.

1.1.4、Glue feeding , profile feeding use digital monitor speed adjusting, digital monitor glue level, profile speed (make sure each glue injection capacity is same, reduce profile scrap ratio).

1.1.5、Proportion monitor(time monitor, prohibit A glue and B glue proportion is not same, waste glue). 1.1.6、A glue and B glue has automatic temperature controller device. 1

.1.7、A glue and B glue pump use imported oil motor drive(make sure glue injection steadily).

1.1.8、A glue and B glue use 2 set of Ingersoll rand diaphragm pump, automatically feeding glue to bottle.

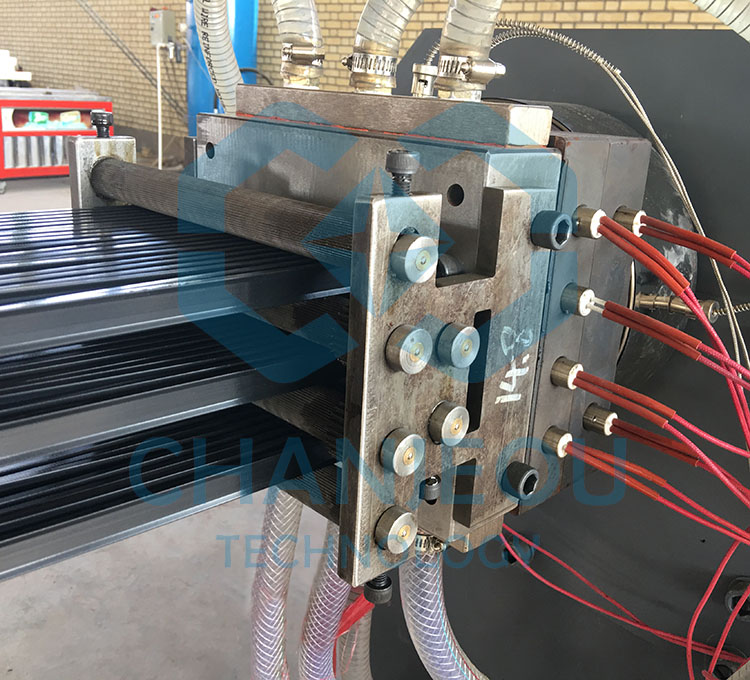

1.1.9、Injection head use America high speed oil motor mixer, maximum rotation is 12500r/min.

1.1.10 、 Use adjustable timing rotation function(prohibit pipe block).

1.1.11、Mixer has auto cleaner and manual cleaner.

1.1.12、Mixer will not produce temperature(make sure glue quality during injection).

1.1.13、Injection machine has air suction device, suction harmful air to outside, reduce pollution. 1.1.14、Has profile feeding and back function.

1.1.15、A/B glue level has monitor and alarm function.

1.1.16、Glue bottle use 3mm stainless material.

1.1.17、Touch screen and PLC use Siemens.

1.1.18、Button use Germany ABB brand.

1.1.19、Injection head cylinder use Japan SMC brand.

1.1.20、Feeding roller, drive roller has upper&lower adjusting function(suitable for all kinds of injection). 1.1.21、A/B glue pipe has filer device.

1.1.22、Injection machine and cutting machine has working light, can work 24 hours.

1.1.23、Injection machine has high pressure, low pressure alarm.

1.1.24、Main machine plate use 30mm steel plate, use high precision, chrome craft, which effectively ensure the accuracy of the machine, and easy to clean the panel impurities.

1.1.25、The processing speed is 0~60m/min. The fastest up to 6 seconds for one piece of aluminum (with quick-drying glue); Use general glue for about 12 seconds for one piece of aluminum (6 meters per piece of aluminum).

Contact us:

| melody@chanjeou.com |

| mobile/whats app:+86 13450531604 |