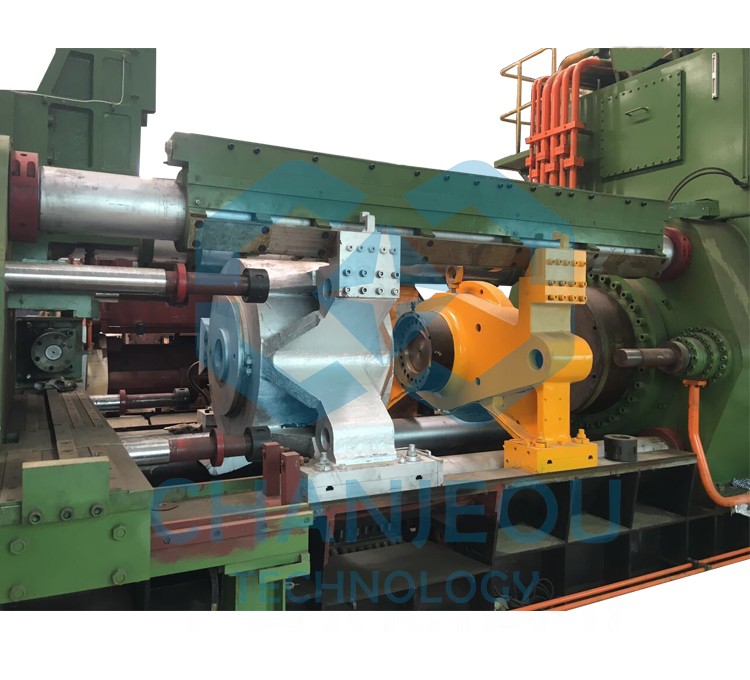

Long Stroke Aluminum Profile Extruder Machine

Brand Chanjeou

Product origin China

Delivery time 6months

Supply capacity 200sets/year

1. Long stroke aluminum extruder machine is stable working traditional and popular design.

2. Mature technology, stable running.

3. Easily operation, simply to understand.

Aluminum billet after heated will be sent to extruder machine,main piston will push aluminum bar into extruder container, start to extrusion.

Long stroke means extrusion press stroke is two times of billet length,it is traditional and mature stable design, easy to operate and understand.

Features of aluminum profile extruder machine:

1. The driving and extruding system is controlled by the main frequency converter by the frequency conversion speed regulating motor, which is passed to the screw step by step through the speed reducing box distribution box and the cross splines, and the program and parameter values entered in the frequency converter are completed, in the equipment factory has been set to complete, can not be changed at will.

2. The heating and cooling system is composed of the barrel heating and cooling, the die head heating and the screw core heating and cooling, and is controlled by the electric cavity program, in addition, a manual forced cooling function is provided to control the instantaneous temperature increase.

Welcome to mail us ,call us or message us for details offer

3. Automatic feeding system is controlled by time relay or level meter to transmit signal, when the shortage of material level meter transmission signal, the system began to feed, feed full level meter signal interrupt, feed stop.

4. Feeding system is also controlled by frequency converter, feeding less, host current and torque reduction. The opposite is true. When the feed is too much, the actual current exceeds its rated current or torque exceeds its set value when the main machine will overload alarm shutdown, generally controlled in the rated value of 50% ~ 80% .

5. Vacuum exhaust system is directly used to control the vacuum pump button to complete, vacuum open solenoid valve open, closed solenoid valve then closed.

Operation procedure of aluminum profile extruder machine production line:

1. Check the oil pressure system is leaking oil, air pressure is normal.

2. Check the conveyor belt, cooling bed, material storage table whether there is any damage and abrasion section.

3. Before drawing, make sure the length of the aluminum profile, then make the drawing rate, determine the drawing length, that is, the position of the main chuck, usually 6063, T5 drawing rate is 0.5% -1% , 6061, T6 drawing rate is 0.8% -1.5% .

4. According to the shape of aluminum section to confirm the clamping method, large section hollow section, can be inserted into the tensile pad, but to ensure that adequate clamping area

5. When the aluminum profile is cooled below 50 ° C, the profile can be stretched.

6. When there are both bending and twisting section, should first correct twisting and then pull bending.

7. The first and second wires are tested to confirm whether the predetermined stretching rate and clamping method are suitable or not. Visual bending, twisting, inspection of the profile plane clearance, flaring, parallel mouth, if not appropriate, to adjust the tensile rate.

8. The operator should be informed to stop extrusion if the normal drawing rate can not eliminate bending, twisting, or pass the geometry.

9. The aluminum profiles on the cooling table can not rub, collide, stack on top of each other to prevent scrapes.

The working efficiency and service life of aluminum extruder machine are closely related to the installation sequence of extruder, in addition to the weight of the equipment itself and the weight of raw materials for production, but also to bear the dynamic load of the extruder work, so the equipment must be installed in accordance with the corresponding installation procedures.

Contact us for more information:

Ms Melody Li

Mobile: +86 13450531604

Email: melodyli98@163.com