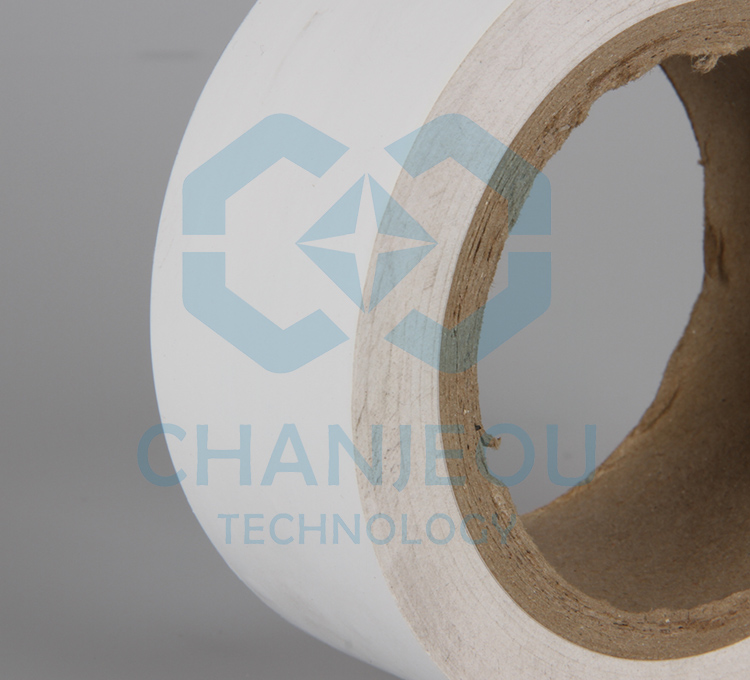

High Temperature Resistant Eva Plastic Protective Film Rolls for Ultrasonic Products Welding Protection Peva Film

Brand CHANJEOU

Product origin FOSHAN

Delivery time 7 DAYS

Supply capacity 3000000 meters

Function: Protect product surface, improve welding quality, optimize production process.

material advantage:has good flexibility, corrosion resistance and electrical insulation, high strength, hardness and transparency, heat resistance and chemical stability, instant temperature resistance of up to 200 degrees Celsius, and can be reused.

Application range, electronic appliances, auto parts, plastic toys, cosmetic containers

High temperature resistant reusable ultrasonic welding film

Ultrasonic film is a protective film used in the ultrasonic welding process. Ultrasonic film is usually made of materials such as PE and PET.

Protecting the surface of parts: The ultrasonic welding film can reduce the damage to the surface of parts caused by ultrasonic pressing, prevent the occurrence of indentation and scorching problems, and is particularly suitable for products with high appearance requirements, such as the shells of household appliances and electronic products.

Enhancing Welding Quality: Ultrasonic welding films can mitigate adverse consequences caused by warping and deformation, fill the gaps on the product surface, effectively reduce local contact pressure, ensure a tight bond between plastic parts and other components, make the welding more robust, and enhance the welding strength and stability of the products.

Optimizing Production Processes: Ultrasonic welding films are beneficial for enhancing the production efficiency of plastic products, reducing waste caused by surface damage or poor welding of the products, and thereby helping enterprises save costs.

Material Characteristics

PE Material: Ultrasonic film possesses excellent flexibility, corrosion resistance and electrical insulation properties, and has a relatively low price. It is a commonly used ultrasonic welding film material. Its thickness usually ranges from 0.06 to 0.15 mm. Ultrasonic film can withstand a temperature of about 200 degrees Celsius for a short period of time, and can be reused. Its usage rate is approximately 8 times that of ordinary PE protective films.

PET material:Ultrasonic film features high strength, hardness and transparency, and has good heat resistance and chemical stability. However, it is relatively expensive.

Scope of Application

Electronics and Electrical Appliance Field: The welding film is used for the welding protection of electronic chips, circuit boards, electronic casings, etc. It helps prevent damage to the precise electronic components during the welding process, ensures the welding quality, and enhances the reliability of the products.

In the automotive parts industry: The welding film can be applied to the welding of automotive interior components, lamp housings, instrument panels and other parts. It protects the appearance and performance of the parts and ensures the quality and safety of automotive parts.

Plastic Toys Sector: In the production of plastic toys, Ultrasonic welding film can protect the paint and patterns on the surface of the toys from being damaged, and at the same time make the welded parts of the toys more stable and secure, thereby extending the service life of the toys.

Cosmetics Container Field: Ultrasonic welding film are used for welding cosmetics bottles, boxes and other containers. They prevent scratches and deformations on the surface of the containers during welding, ensuring the appearance quality and sealing performance of cosmetics containers.

Working principle: In the process of ultrasonic welding, the welding film is between the welding head and the weldment. When the welding head transmits the high-frequency vibration energy generated by the ultrasonic generator to the weldment surface, the welding film is subjected to the combined action of high-frequency vibration and pressure. Due to the characteristics of the welding film material, it can buffer the direct pressure of the welding head on the surface of the weldment to a certain extent, and evenly disperse the ultrasonic energy, so that the energy and pressure on the surface of the weldment are more uniform, thereby reducing the surface damage caused by too high local energy or too much pressure, and help the contact surface of plastics and other welders to better melt and combine.