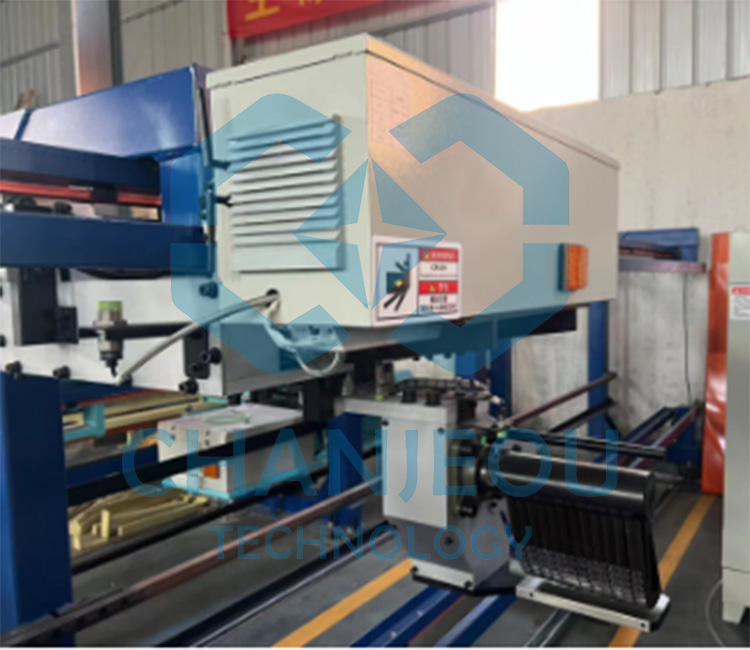

Fast Return Extrusion Double Puller With Flying Saw

Extrusion Double Puller With Flying Saw :

1. P1 And P2 Puller Head, P3 Is Flying Saw For Cutting Aluminum Profile

2. Three Walking Rails, Higher Efficiency

3. All The Actions Of The Tractor Are Completed Automatically, And The Required Parameters Can Be Adjusted By The Electric Control Cabinet, Which Is Safe And Reliable.

4. The Traction Machine Adopts Servo Motor And Precision Guide Rail To Improve The Precision, And Its Displacement And Speed Are Accurate And Controllable.

5. The Tractor Is Driven By Gear And Rack, Without Additional Power Cabinet, Which Is More Economical Than The Traditional Chain Drive.

Fast Return Extrusion Double Puller With Flying Saw main features:

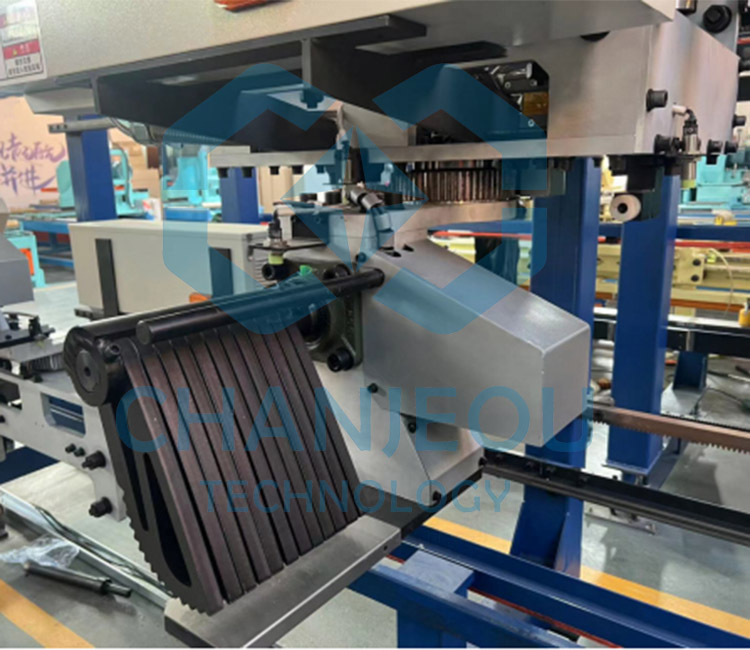

1. The new-type special-shaped tooth clamps of the tractor press material, adapt to various shapes of aluminum, can better press aluminum profiles.

2. Automatic saw by the full server control, accurate control of cutting distance, reduce waste rate, and can adjust according to the needs of advance and retreat speed.

3. The frame is made up of up and down precision elevator guide rail structure, which can ensure the two vehicles to go back and forth alternately and stably without bumping.

4. The machine can work round the clock to increase productivity.

5. Upper and lower two independent double guide rail design, guide rail use elevator guide rail. The guide rail support frame uses square tube, the steel material selects the structure to be solid,To ensure the stable operation of the head, to ensure adequate strength, solid and durable;

6. Servo motor control

7. Most of electrical parts is Schneider brand

5inch(1000MT) extrusion double puller main parameters:

1. Synchronous pulling: 10~120KG

2. Pulling speed: 60m/min

3. Maximum return speed: 180m/min

4. Operation : manual/auto

5. Control system: COTRUST

6. Guide rail : 100mm×100mm

7. Automatic saw length: 5 m

8. Diameter of saw blade: Ø500mm

9. Effective clamp size: 130mm*320mm

10. Automatic saw drum length: 350mm