Extrusion Press Container

Brand Chanjeou

Product origin China

Delivery time 30days

Supply capacity 1000pcs/set

1. Suitable heating method improve extrusion press container quality, enhance the bearing capacity,extend use life.

2. if container is deformation,only need change the liner, reduce material consumption, save cost.

3. extrusion press container make sure the container could use in high temperature, high pressure, high friction condition for long and reliable working.

Two kinds of heating method for extrusion press container

1. wrap-around heating type

Advantage:

good thermal insulation effect, material price is lower relatively.

Disadvantage:

when need change wrap-around heating pipe, need disassembly container,Slow heating from room temperature to extrusion temperature relatively.

2. plug-in heating type

Advantage:

fast heating from room temperature to extrusion temperature relatively,convenient to change, no need to disassembly extrusion press container.

Disadvantage:

regular thermal insulation effect, material price is higher relatively.

Material of container:

1. container seat: 35# cast steel

2. container outside sleeve: 5CrMnMo

3. container insde sleeve: H13

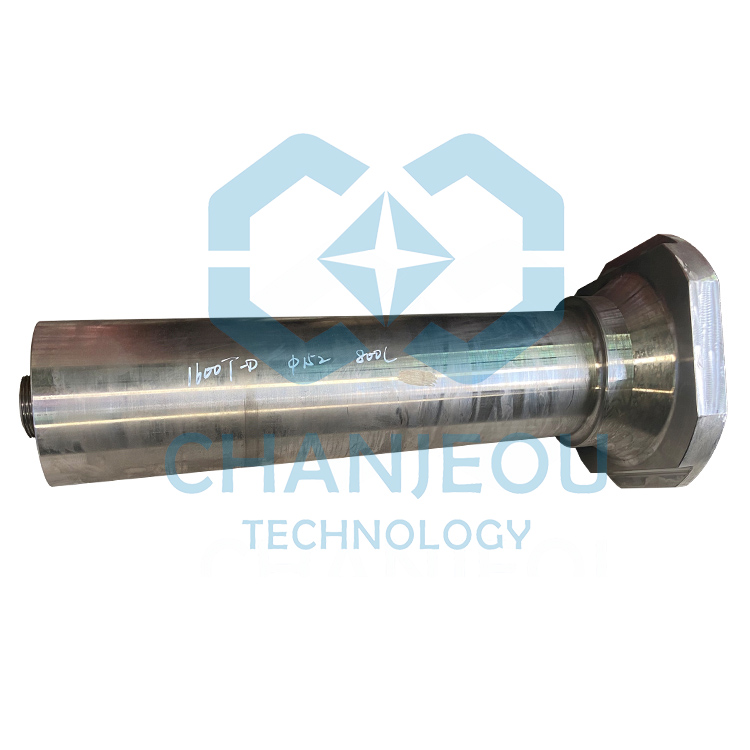

Extrusion Press Stem:

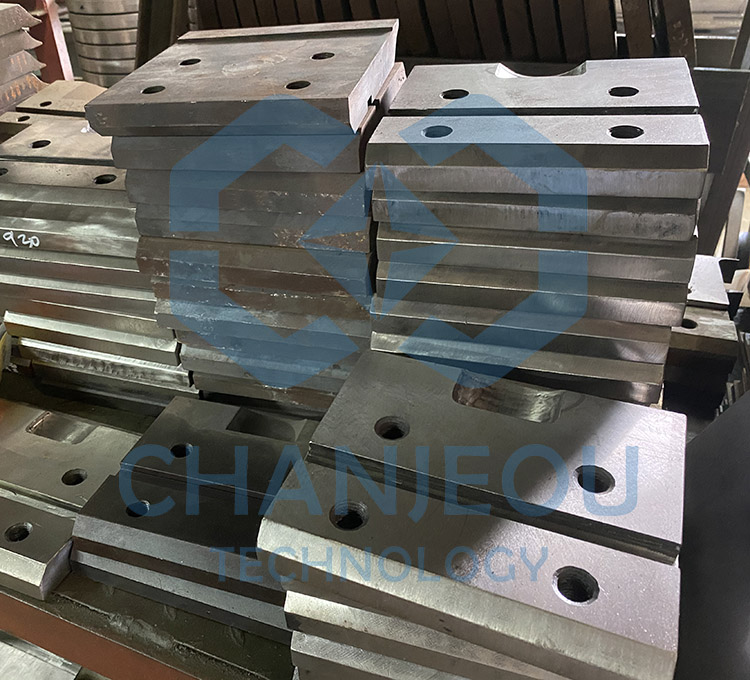

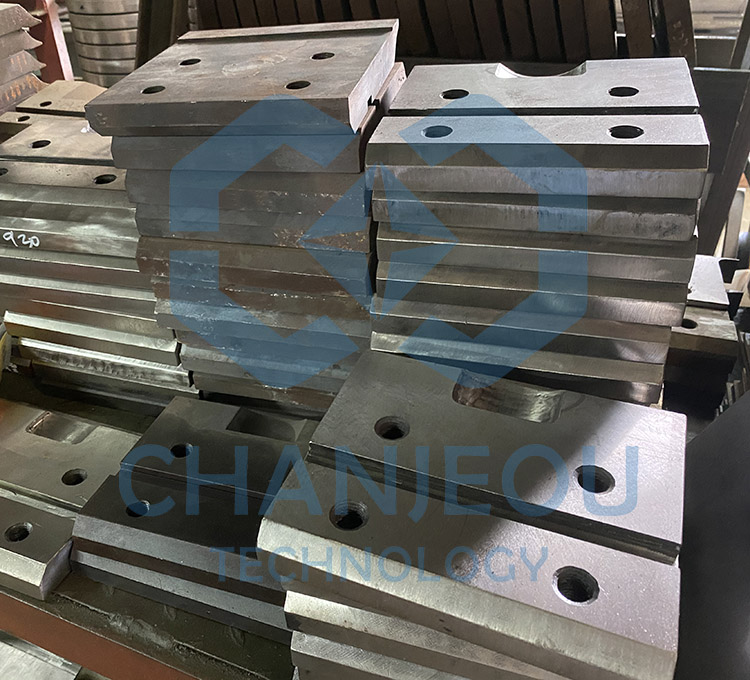

Extrusion press machine shear blade

Extrusion die seat:

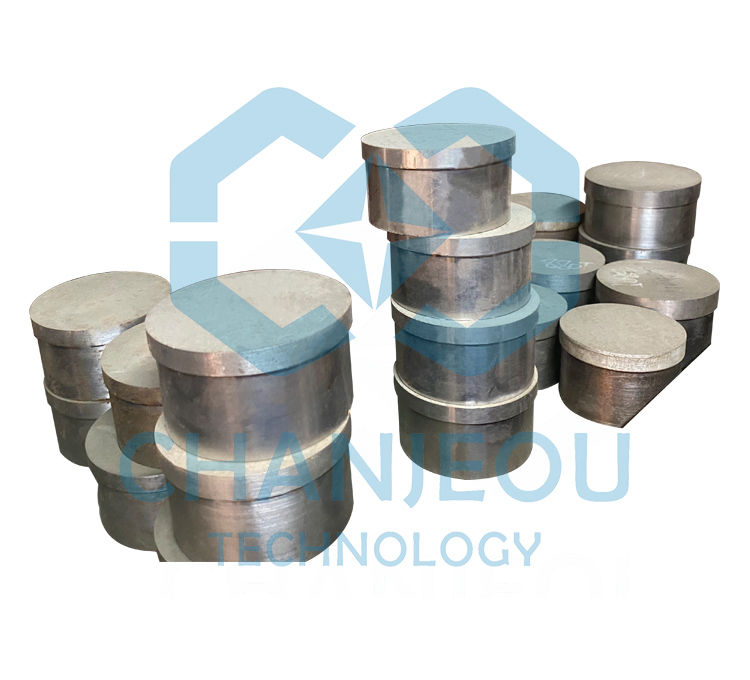

Active dummy block for extrusion:

Fixed dummy blcok for press machine: