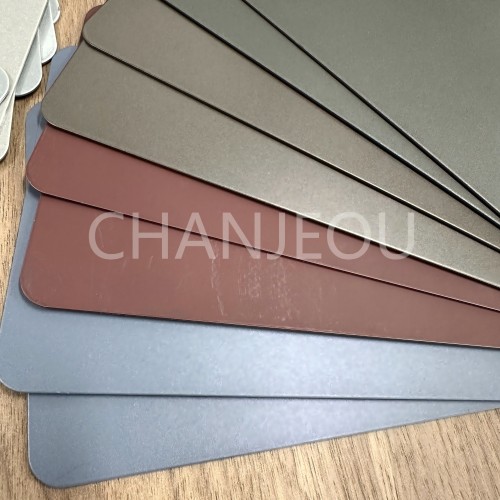

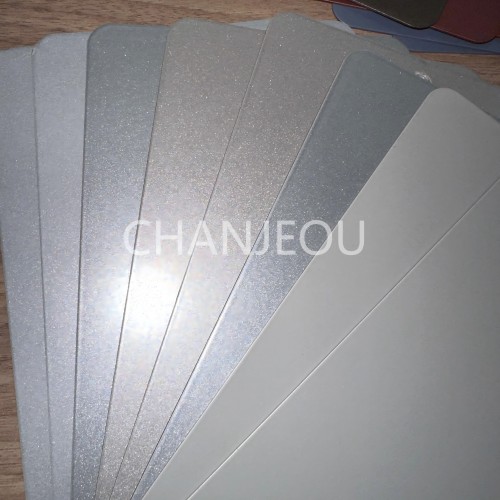

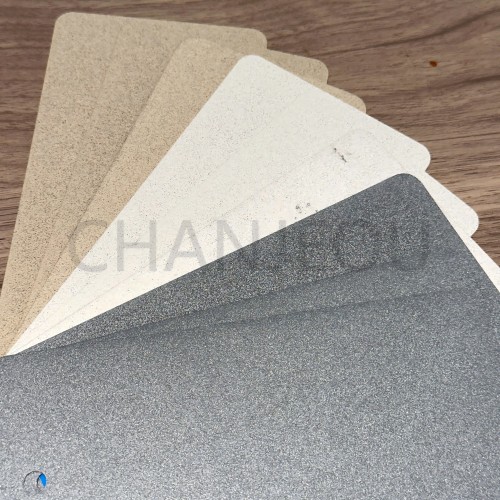

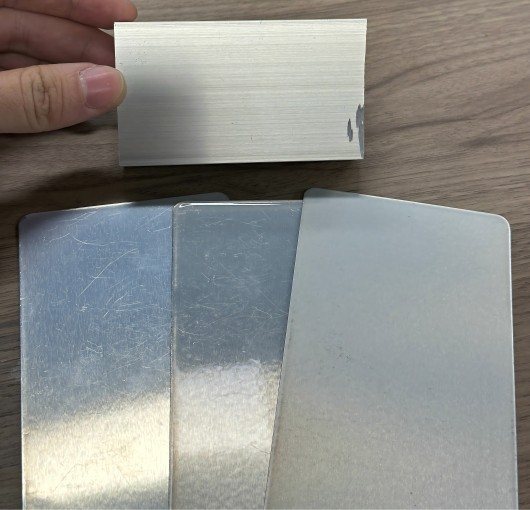

Electrostatic spraying powder

Brand CHANJEOU

Product origin FOSHAN

Delivery time 7 DAYS

Supply capacity 3000000 ton

Good environmental protection, high quality coating, efficient construction and excellent economy

Electrostatic spraying is a coating technology that evenly applies the coating to the surface of an object by means of the principle of static electricity,

it has remarkable advantages:

Strong weather resistance:Strong weather resistance: in high temperature, cold, wet, strong ultraviolet irradiation and other environments, powder coating is not easy to powder, fade, crack and other phenomena, can maintain good appearance and performance for a long time, especially suitable for outdoor facilities painting.

High utilization rate of the coating: Under the action of the electric field force, the coating particles are directionally adsorbed on the surface of the object to be coated, greatly reducing scattering and waste. Compared with traditional air spraying, the utilization rate can reach 80% - 90%, effectively reducing the coating cost.

Excellent coating quality: It can make the coating particles evenly distributed, forming a coating with uniform thickness, smooth and flat surface, and strong adhesion. The electrostatic effect enables it to better fill the tiny pores on the surface of the object, improving the compactness and anti-corrosion performance of the coating and prolonging the service life of the object.

High production efficiency: It can achieve automated operation and can carry out continuous and rapid spraying. The film formed in one spraying is relatively thick, and generally, a single spraying can reach the required thickness, reducing the number of sprayings and drying times and improving production efficiency.

Superior environmental performance: Due to the high utilization rate of the coating, it reduces waste and volatilization, lowers the content of volatile organic compounds (VOCs) in the air, and causes less pollution to the environment. The equipment is equipped with a recycling device, which can recycle the coating that has not adhered, reducing the generation of waste.

Good safety performance: Water-based or high-solid-content coatings are commonly used. These coating have a high flash point, are not prone to combustion and explosion, and are safer than traditional solvent-based coatings. In the design and use of the equipment, measures such as grounding and static electricity elimination are taken to prevent the accumulation of static electricity and spark discharge, ensuring the safety of the spraying process.

We can support custom color, if you need, please send the sample to us.

WhatsApp:86 13672690566

Email:Jay@chanjeou.com