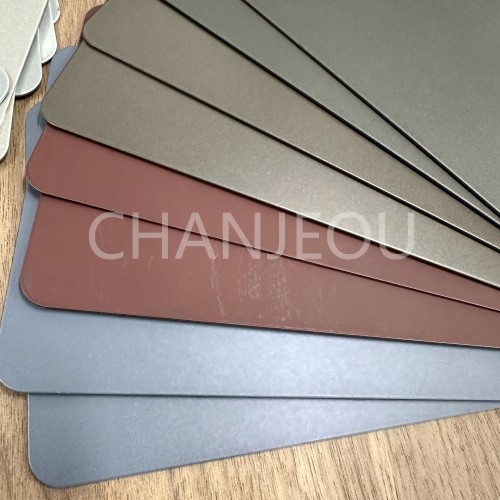

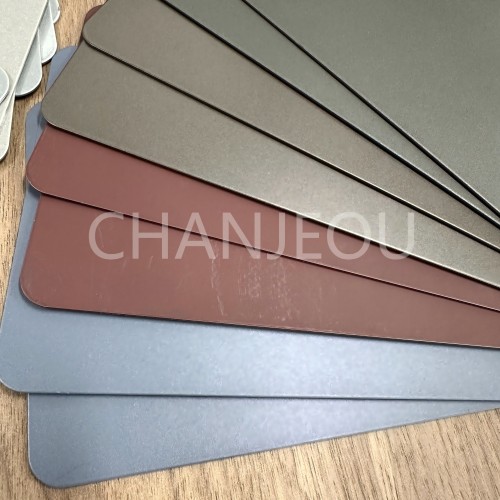

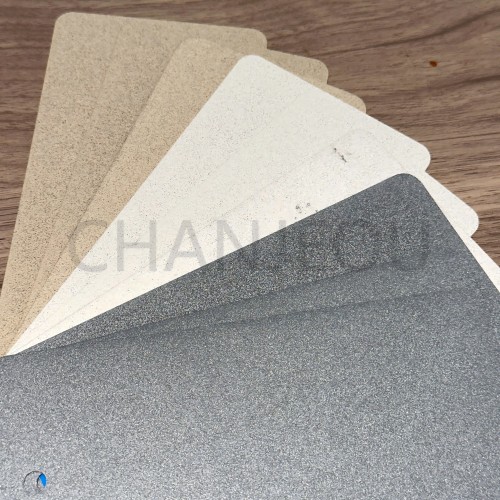

electrostatic spraying coating powder for aluminum profile

Brand CHANJEOU

Product origin FOSHAN

Delivery time 7 DAYS

Supply capacity 5000000

Powder coating is a new technology in surface coating technology, which is a coating process in powder form and form a coating film. In many cases, it can replace the traditional painting process

coating powder

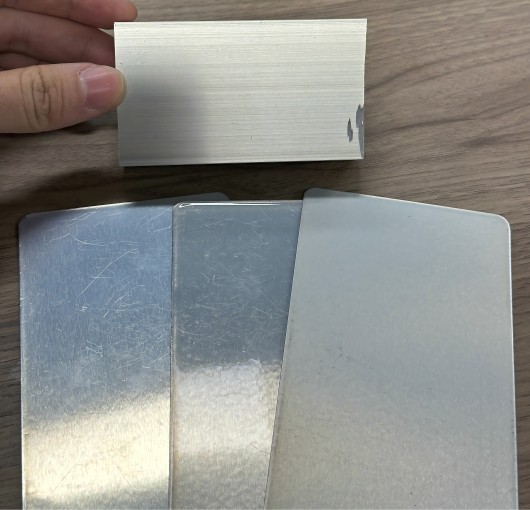

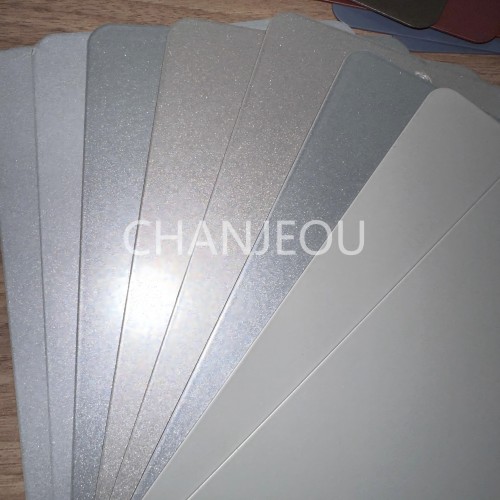

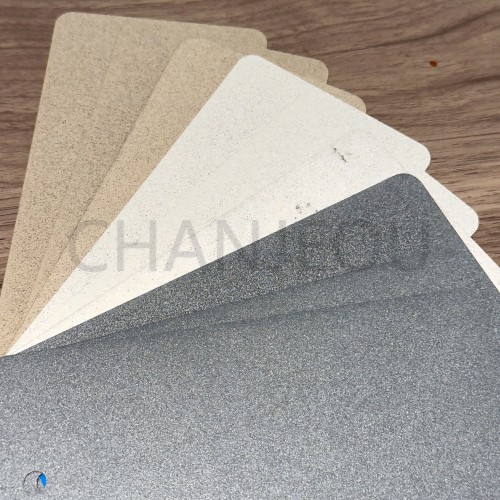

Powder coating using the principle of electrostatic spraying of dry powder adsorption in the metal aluminum profile after 200 ℃ high temperature grill after the powder cured into a layer of about 60 microns thick solid bright coating. Make the product surface smooth and even color with strong acid resistance, alkali resistance, impact resistance, abrasion resistance can withstand strong ultraviolet radiation and acid rain for a long time erosion does not appear coating chalking, fading, peeling and other phenomena. Powder coated aluminum profiles have a service life of 30 years under normal conditions. Its surface coating in 5-10 years to ensure that the color does not fade, does not change color, does not crack. Its weather resistance and corrosion are better than ordinary aluminum color diversity.

The coatings are made of special resin, pigment filler, curing agent and other additives, mixed in a certain proportion, and then prepared through the process of hot extrusion and crushing and sieving. They are at room temperature, storage stability, by electrostatic spraying, friction spraying (thermosetting method) or fluidized bed dip coating (thermoplastic method), and then heated and baked melt curing, so that the formation of smooth and bright permanent coating film, to achieve the purpose of decoration and corrosion prevention.

Its characteristics are:

1. the product does not contain toxicity, does not contain solvents and does not contain volatile toxic substances, so there is no poisoning, no fire, no “three wastes” emissions and other public hazards, in full compliance with the requirements of the National Environmental Protection Act. 2. high utilization rate of raw materials, some well-known brands of powder suppliers to produce powder, its overspray powder can be recycled, the highest utilization rate can even reach more than 99%. 3. After pre-treatment of the coated object, one-time construction, without primer, yess of the coating film, easy to realize automation, high production efficiency, can reduce costs.

4. dense coating, adhesion, impact strength and toughness are good, high corner coverage, excellent chemical resistance and electrical insulation properties. 5. powder coating storage, transportation safety and convenience.

Compared with the traditional paint process, the advantages of powder coating are:

1. high efficiency: due to a one-time film, can improve productivity 30-40% 2, energy saving: reduce energy consumption by about 30 3. less pollution: no organic solvent volatilization (does not contain paint coatings in toluene, xylene and other harmful gases). 4. high utilization rate of paint: up to 95% or more, and powder recycling can be used many times. 5. good film performance: one-time film thickness of up to 50-80μm, its adhesion, corrosion resistance and other comprehensive indicators are better than the paint process. 6. High yield: before curing, it can be repainted twice. There are more kinds of powder coating process, the common ones are electrostatic powder spraying and dip molding.

Powder coating is a new type of solvent-free 100% solid powder coating. With no solvent, no pollution, saving energy and resources, reduce labor intensity and coating film mechanical strength and high characteristics. It has three major categories: thermoplastic powder coating (PE), thermosetting powder coating, architectural powder coating.