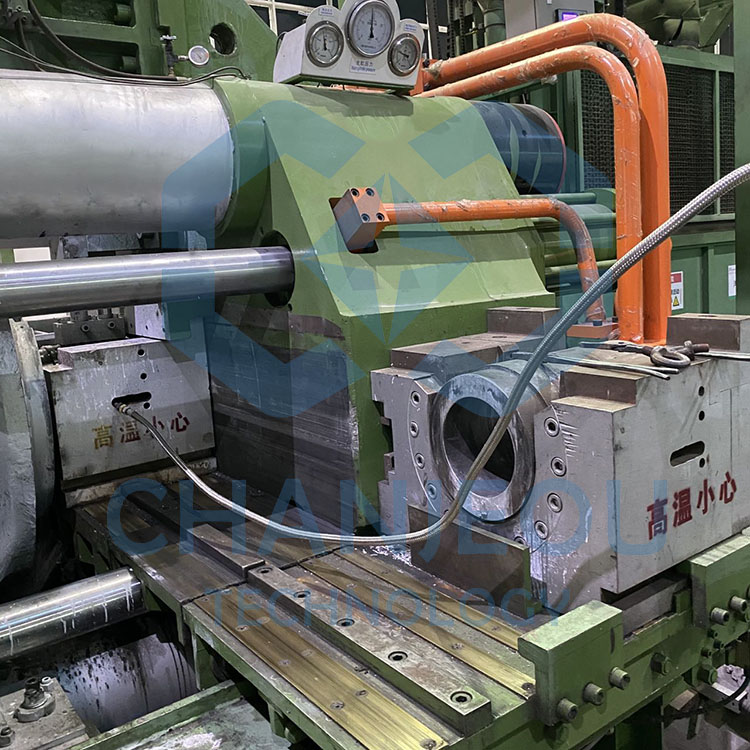

Constant Speed Aluminium Profile Extrusion Machine

Aluminium profile extrusion machine main features:

1. Public authorized billet loading method.

2. Non-extrusion time is short, higher production yield.

3. Main pump of hydraulic system is advanced proportion pump, constant speed is more precision, more stable working, more energy saving.

4. Plug-in heating for extrusion container, area separately control for temperature.

5. Key parts adopt forged and casting treatment.

6. Sporty section adopt full automatic oil lubrication.

7. Use prestressed structure, highly reduce the deformation.

8. Locking device for extrusion head, extend use life.

9. Extrusion die base locking function, reduce shaking, improve product quality, good at multiple cavity extrusion.

1150UST(5inch) extrusion press main details:

1. short stroke design, reduce non-extrusion time

2. front platen extrusion mouth: Dia,160*220mm

3. working pressure: 210Bar

4. maximum billet length: 700mm

5. minimum billet length: 400mm

6. maximum extrusion speed: 10mm/sec

7. non-extrusion time: 16s

8. total power: 203kw

9. overall dimension: Length 12700mm*W4210mm*H4220mm

Main cylinder parameters:

1. working pressure: 210Bar

2. plunger diameter: 755mm

3. plunger pushing force: 939.7MT

4. maximum stroke: 800mm

Side cylinder parameters:

1. working pressure: 210Bar

2. cylinder diameter: 180mm

3. rod diameter: 130mm

4. total pushing force: 106.8MT

5. return force: 51MT

6. maximum stroke: 800mm

Extrusion container locking cylinder:

1. working pressure: 180bar

2. cylinder diameter: 160mm

3. rod diameter: 110mm

4. extrusion die locking tension: 144MT

5. maximum stroke: 350mm

Extrusion die moving cylinder:

1. working pressure: 210bar

2. cylinder diameter: 80mm

3. rod diameter: 35mm

4. pushing force: 5MT

5. return force: 4MT

6. maximum stroke: 580mm

Aluminum scrap remaining cylinder:

1. working pressure: 100bar

2. cylinder diameter: 80mm

3. rod cylinder: 35mm

4. pushing force: 5MT

5. return force: 4MT

6. maximum stroke: 580mm