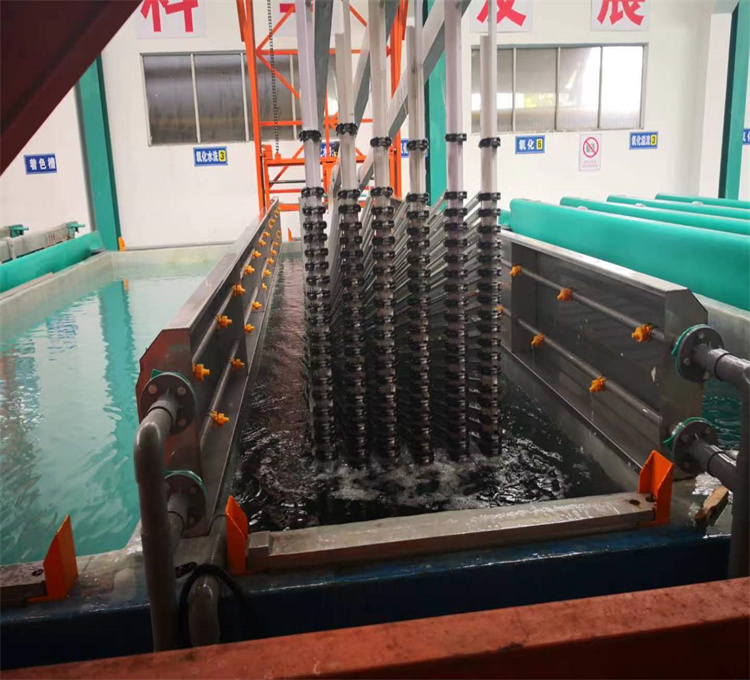

Aluminium Profile Anodizing Machine

1. Aluminum profile anodizing machine is used for aluminum anodizing treatment.

2. Equip with electrophoresis treatment tank.

3. Full automatic and semi automatic design, manual operation design are optional.

4. Advanced electrical componenets, good quality rectifier and cooling machine.

Aluminum Profile Anodizing Line is chemical treatment equipment for aluminum profile ,including anodizing tank, coloring tank, water cleaning tank, sealing tank, electrophoresis tank etc

Send us your anodizing thickness ,color type, space size,maximum profile length, monthly capacity, profile section area , will design layout free of charge, send reasonable offer with top quality.

When choose aluminum profile anodizing plant, there some important information should be consider:

1, IGBT or SCR rectifier? IGBT rectifier save 6% electricity, but complicated control system , little hard for customer to maintenance SCR rectifier simple control system, easier to maintain, price is little high, more stable working |

2,rectifier with water cooling or air cooling ? water cooling is better, cooling effect is better, but rectifier price is little higher in temperature lower place, air cooling is good working. |

3,indirect chiller or direct chiller? indirect chiller means anodizing and coloring tanks use same chiller, it is good for small capacity anodizing line, save machine cost. direct chiller means anodizing and coloring tanks use different chiller, it is good for big capacity anodizing plant, high efficiency. |

4.room temperature sealing, moderate temperature sealing or high temperature sealing? if only compare sealing effect, high temperature sealing effect is best if compare sealing effect and production price, moderate sealing is best choice. moderate temperature sealing:50~60 degree high temperature sealing:80~90 degree |

5.U type design or straight type design? Normally, suggest U type design, same tanks quantity, production efficiency is higher; if limit of space, no other choice, then accept straight type anodizing production line. |

6.where have waterflow tanks? Normally these tanks later have waterflow tank: two anodizing tanks with one overflow tank Overflow tank is used for keep uniform for anodizing chemical |

7.which tank have heating? 1, Alkaline tank 2,Hot water rinsing |

8.which tank need suction chemical smell? 1, anodizing tank 2,Etching tank |

9,does aluminum profile oxidizing plant equip with chemical smell suction device yes, supply together |

10. need ETP machine? wasted water treatment machine? optional, give us standard, we can supply |

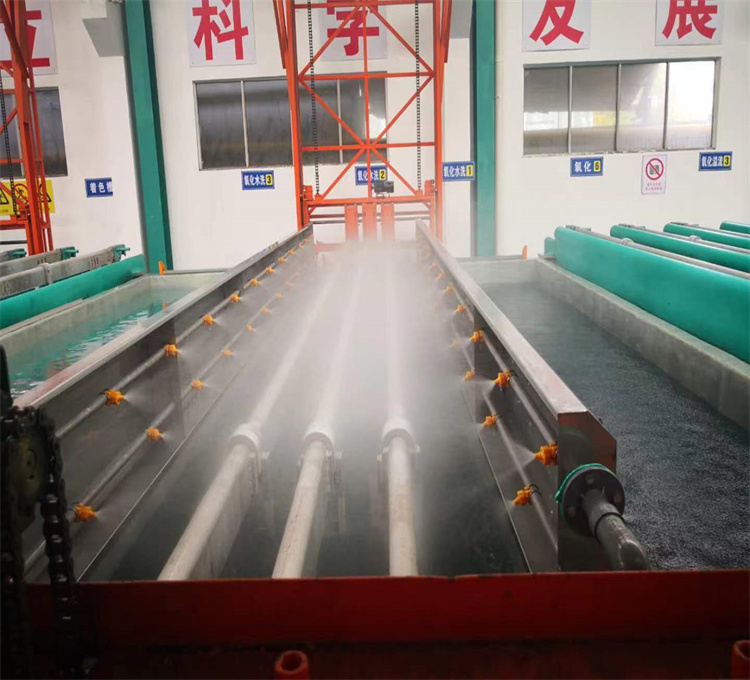

11. how about waterspraying tank? water spraying tank follow Etching tank, neutralize tank and anodizing tank. |

Contact us for design layout and more information:

email:melody@chanjeou.com |

| www.chanjeou.com |

| whats app:+86 13450531604 |