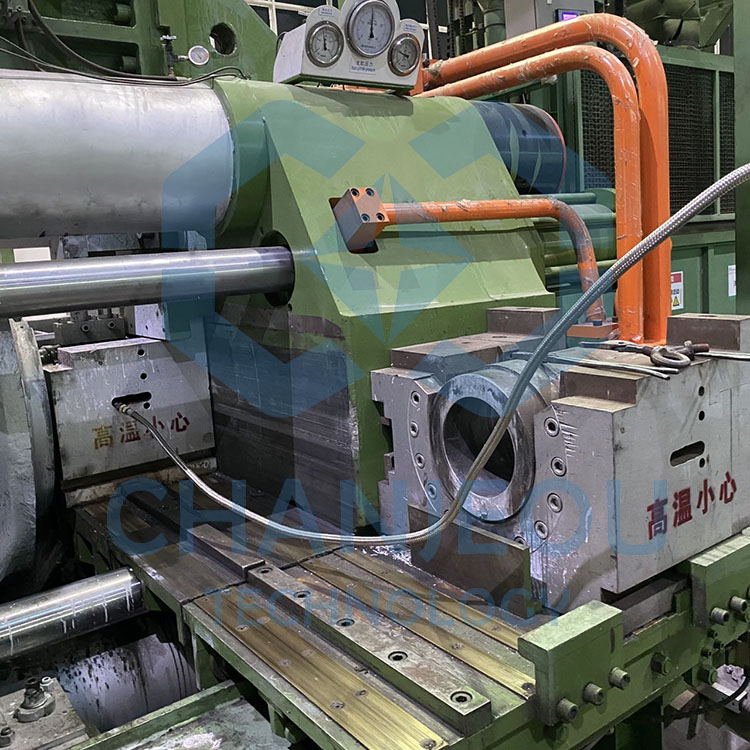

Aluminium Extrusion Press Machine

Brand Chanjeou

Product origin China

Delivery time 6months

Supply capacity 200sets/year

1. 8inch Long stroke back loading extrusion press, discharge gate is customized on basis of extrusion aluminum profile.

2. Billet length is 1100mm ,Diameter is 203mm,fixed stem design.

3. 210kgs pressure design, pressure increasing capacity is available on basis of 210kgs pressure, stable working,superior sales service.

4. All paremeters could be design on basis of customer requirements.

8inch long stroke back loading aluminum profile extrusion press parts free of charge:

(1). stem

(2). dummy block

(3). heaters

(4). shear blade

(5). container:

(6). sealing parts of oil cylinder

(7). operation tools

(8). button

Main paramters of 8inch extrusion press machine:

1. working pressure: 210kgf/cm2

2. container cylinder capacity: 2217T

3. billet size: dia,203mm*1100mm(L)

4. Stem structure: fixed type

5. front platen hole dimension(discharge size): dia,230*340mm, corth radius 100

6. main cylinder diameter: 1100mm

7. extrusion capacity: 1995T

8. side cylinder extrusion capacity: 222.88T

9. container size: dia,220mm

10. die size: dia,450mm*450mm

11. extrusion time: 15mm/sec

12. dead cycle time: 25sec

Main material list of 8inch extrusion press :

1. Mian hydraulic pump: Germany Rexroth

2. PLC: Mitsubishi or Siemens

3. Touch panel: 10inch Porface

4. main cylinder: forged

5. stem: H13

Design description:

Extrusion press have two kinds of design

1. long stroke:

(1). extrusion stem walk two billets length distance.

(2). short billet move from billet heating furnace to extrusion press by chain type conveyor.

2. short stroke:

(1). extrusion stem walk one billet length distance.

(2). short billet move from billet heating furnace to extrsion press by crane type device, save space.

3. frequency conversation design(VFD) help extrusion press to save 15~20% energy.