What are the uses of aluminum honeycomb panels?

Honeycomb panel is a kind of composite material with a sandwich structure, which is formed by bonding two thin face panels with a honeycomb core in the middle through methods such as gluing. The following are its common classifications, applications, and advantages:

Classifications

Classification by Material

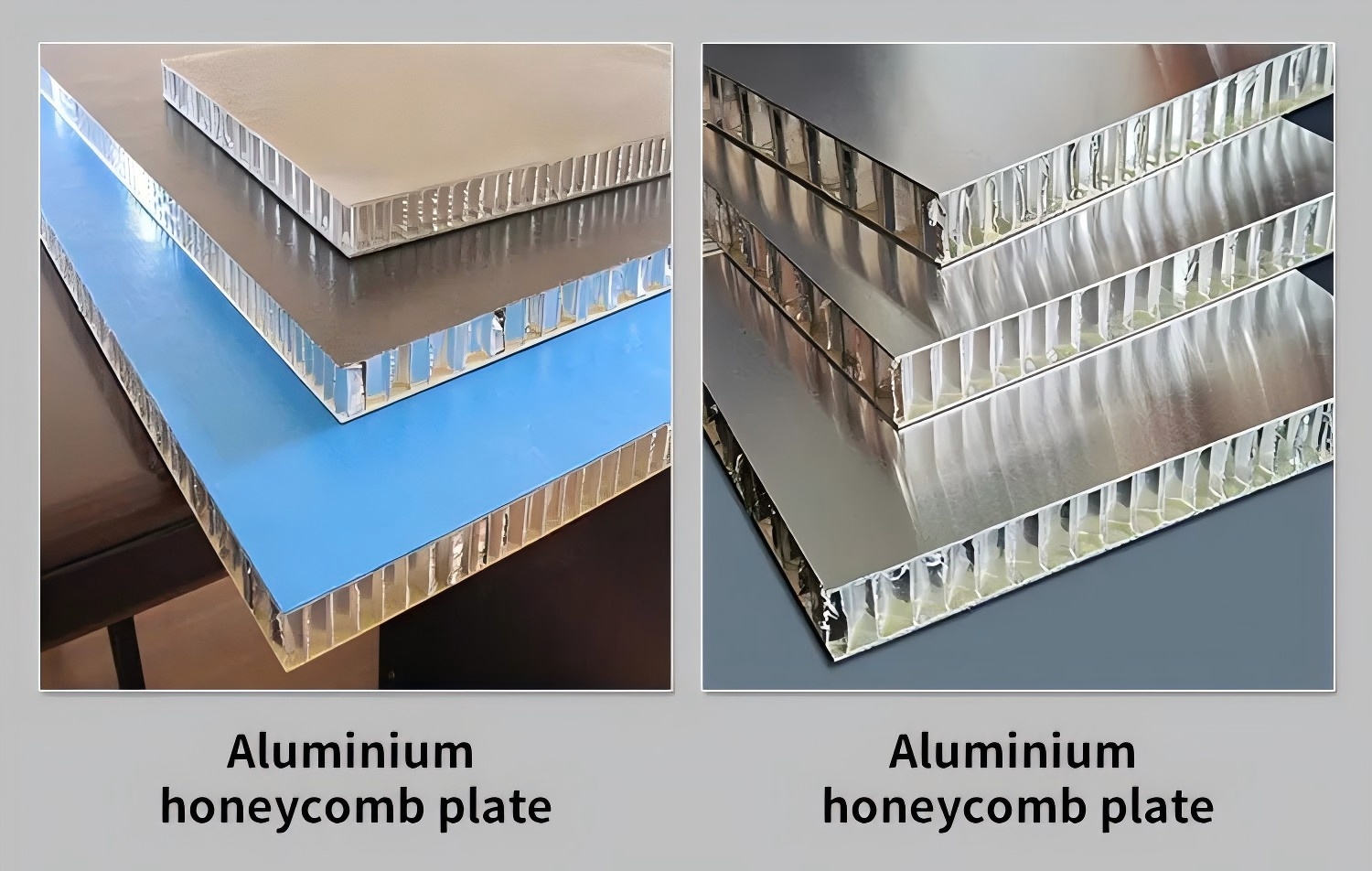

Aluminum honeycomb panel: With aluminum alloy as the face panel and honeycomb core material, it has the advantages of light weight, high strength, corrosion resistance, fire prevention, and moisture resistance. It is the most widely used type of honeycomb panel and is commonly applied in fields such as architectural decoration, aerospace, and automotive manufacturing.

Paper honeycomb panel: The honeycomb core is made of paper, and the face panel can be made of paper, wood, or other materials. Paper honeycomb panels have the characteristics of low cost, light weight, and environmental friendliness. However, their strength is relatively low, and they are mainly used in fields with relatively low strength requirements, such as packaging and furniture.

Plastic honeycomb panel: The honeycomb core and face panel are made of plastic materials, which endow it with good corrosion resistance, insulation, and water resistance. Plastic honeycomb panels are often used in fields such as advertising displays, logistics transportation, and building insulation.

Classification by Application

Honeycomb panels for construction: Usually, they have high strength and fire resistance, and the surface treatment is diverse. They are used for the decoration of interior and exterior walls of buildings, curtain walls, suspended ceilings, etc., and can meet the aesthetic and functional requirements of buildings.

-Honeycomb panels for furniture: They focus on the flatness and decorativeness of the surface and can be used to make cabinet doors, tabletops, cabinet bodies, etc. of furniture, providing good support and aesthetic effects.

Honeycomb panels for packaging: They emphasize cushioning performance and economy and are mainly used for packaging large and fragile items, such as household appliances and glass products, effectively protecting the items from damage during transportation.

Applications

In the construction field: They are used for the thermal insulation and sound insulation of building exterior walls, which can improve the energy efficiency and living comfort of buildings. They are also used for interior partitions in buildings, which can divide spaces and have certain sound insulation and fire prevention functions.

In the furniture field: They can be made into various furniture components, such as drawer fronts and shelves, providing stable structural support for furniture. At the same time, since their surface can be treated with a variety of decorative methods, they can meet different design style requirements.

In the packaging field: As packaging materials, they can be made into packaging boxes, pallets, etc. They can bear a relatively large weight and provide good cushioning protection for the packaged items. They are widely used in the transportation packaging of electronic, mechanical, and other products.

In other fields: In aerospace and shipbuilding, they are used to manufacture structural components of the fuselage and hull to reduce weight and ensure strength. In the advertising industry, they are used to make billboards, display racks, etc., and have the characteristics of light weight, durability, and strong customizability.

Advantages

Light weight and high strength: The honeycomb structure enables the honeycomb panel to maintain high strength and stiffness while being relatively light in weight. Its specific strength and specific stiffness are much higher than those of ordinary panels.

Good sound insulation and heat insulation performance: The air in the honeycomb core can prevent the propagation of sound and heat, giving the honeycomb panel good sound insulation and heat insulation effects, which can effectively reduce indoor noise and regulate the temperature.

Excellent shock absorption and cushioning performance: When subjected to external impact, the honeycomb panel can absorb energy through the deformation of the honeycomb core, playing a role in shock absorption and cushioning, which is important for protecting internal items or structures.

Environmental protection and energy conservation: Some honeycomb panels are made of renewable materials, such as paper honeycomb panels, which meet environmental protection requirements. At the same time, their sound insulation and heat insulation performance helps to reduce the energy consumption of buildings, achieving energy conservation effects.

Good processing performance: The honeycomb panel can be processed according to needs, such as cutting, bending, stamping, etc., to be made into products of various shapes and sizes to meet the requirements of different application scenarios. Moreover, its surface can be treated with a variety of decorative methods, such as painting and laminating, and has good decorativeness.

if you want know more please conact me

whatsAPP:86 13672690566

Email:jay@chanjeou.com