Extrusion Aluminium Profile Anodising Machine China Manufacturer

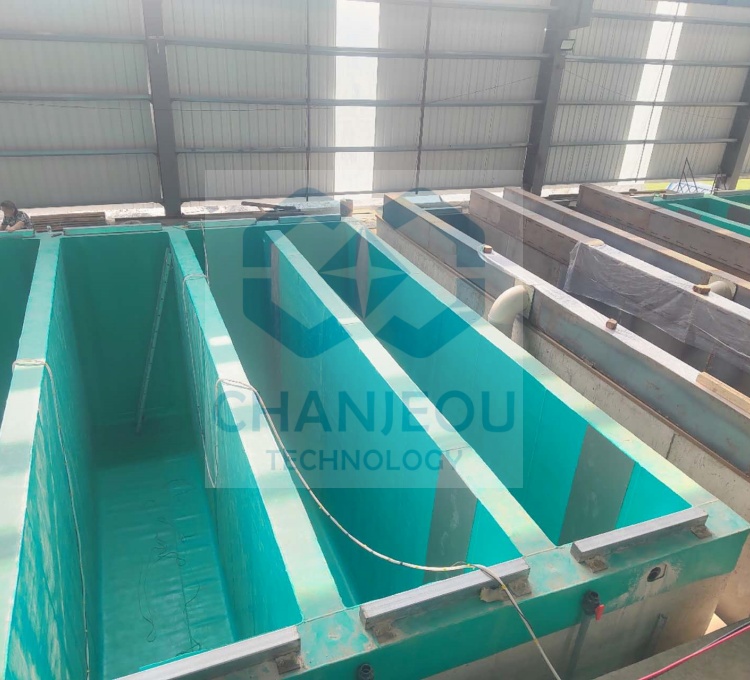

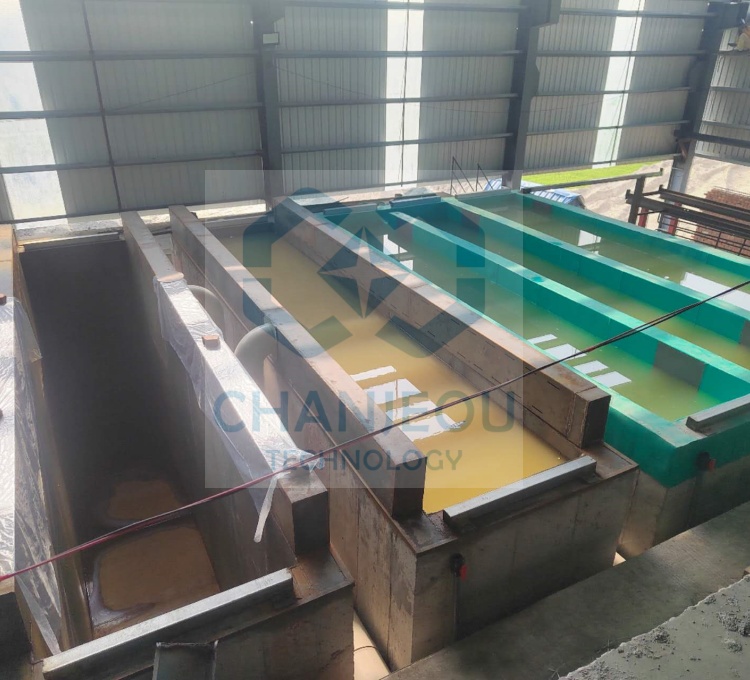

Chanjeou Technology company is China manufacturer for aluminium extrusion profile anodising machine,send one set of 800Tons anodising machine to Bangladesh, right now, under installation, after welding the PVC anti-corrosion material, testing the leakage purpose by water.

How to choose the extrusion aluminium profile anodising machine ?

1, tank type for extrusion aluminium profile anodising machine

PP tank or SS tank or PVC tank?

2,chiller type for aluminium extrusion profile anodising machine

direct chiller or indirect chiller?

3,hot water heating type for extrusion aluminium profile anodising machine?

steam water boiler or natural gas/LPG/diesel oil/electricity boiler?

4,crane type for anodising machine?

manual/semi automatic/full automatic?

5,rectifier type?

IGBT or SCR rectifier with water or air cooling?

6,anodising thickness?

8~15um or 15~25um?

7,U type or straight type for extrusion profile anodising machine?

U type for better transport, improve efficiency

Straight type save space

Thickness standard for anodising

1. Aluminum alloy anodisizing film: In the field of architectural decoration, aluminum alloy anodized film is divided into four levels according to the usage environment: AA10, AA15, AA20, and AA25. The average thickness of AA10 grade oxide film is not less than 10 μ m, and the local thickness is not less than 8 μ m, suitable for general indoor environments; The average thickness of AA15 grade is not less than 15 μ m, and the local thickness is not less than 12 μ m. It can be used in indoor environments with certain corrosiveness; The average thickness of AA20 grade is not less than 20 μ m, and the local thickness is not less than 16 μ m, suitable for general outdoor environments; The average thickness of AA25 grade is not less than 25 μ m, and the local thickness is not less than 20 μ m. It can be used in outdoor highly corrosive environments.

2. anodising film on steel parts (bluish or blackened): Generally, the thickness of the oxidation film on steel parts is relatively thin, usually between 0.5 and 1.5 μ m. For protective decorative steel with bluing or blackening treatment, the film thickness within this range can provide certain rust prevention ability and aesthetic appearance.

3. Titanium alloy electroplating film: The thickness of the anodic oxide film on titanium alloys used in high-end fields such as aerospace depends on specific application requirements. For general protective and decorative purposes, the thickness of the oxide film may be around 15 μ m; And for some special functions, such as improving wear resistance, electrical insulation, etc., the thickness of the oxide film may reach 10 μ m or even higher.

4. Copper and copper alloy anodising film: For the oxidation treatment of copper and copper alloys, such as copper oxide films used for protection and decoration, the thickness is usually between 0.5 and 5 μ m. According to different usage environments and requirements, the thickness of the film layer can be adjusted by controlling the oxidation process to obtain suitable protective and decorative effects