Cars,Military Parts,Chiller Parts Aluminum Hard Coat Anodizing Treatment Production Plant

Cars,Military Parts,Chiller Parts Aluminum Hard Coat Anodizing Treatment Production Plant:

1,Anodizing thickness is higher

2,Chiller is more higher requirements

3,Rectifier is more higher voltage

Difference between regular aluminum anodizing treatment line and hard coat anodizing treatment production:

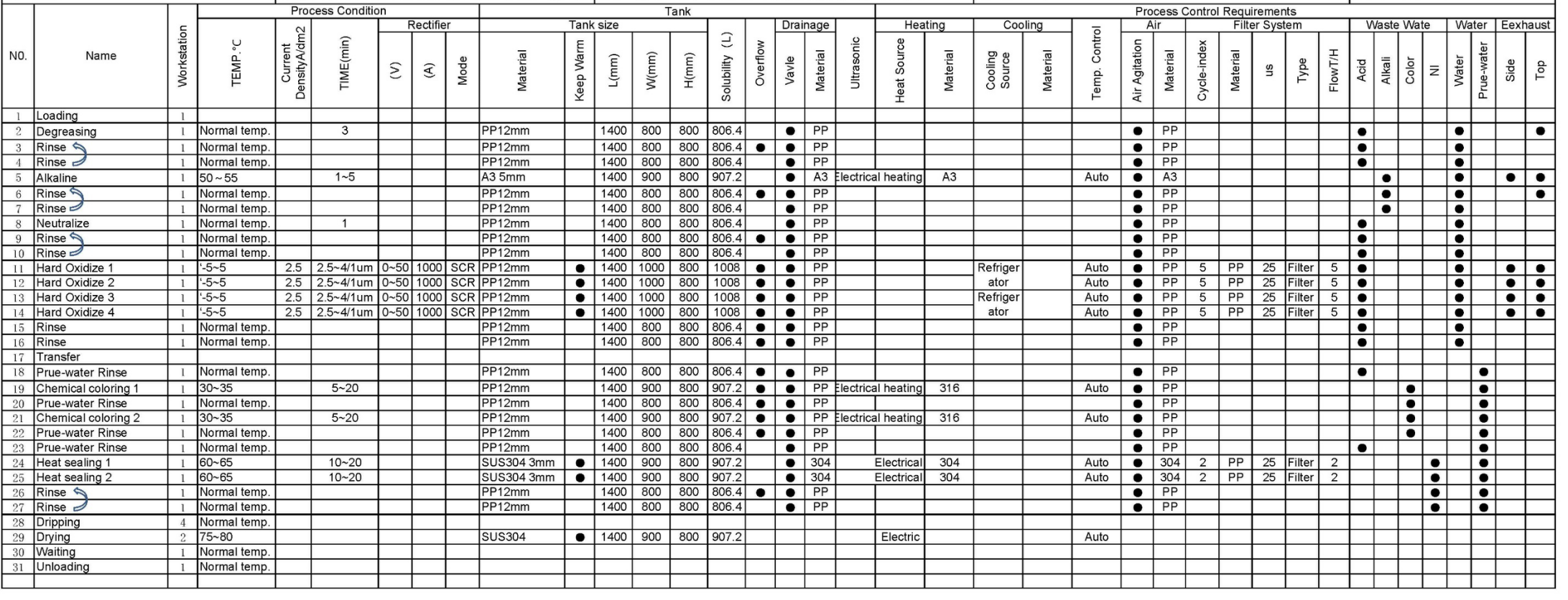

| Item | Regular anodizing line | Hard coat anodizing line |

| Anodizing thickness | maxium 25um | maximum 50um, minimum 20um |

| anodizing time | 1um/2.6min | 30um/1 hour |

| anodizing temperature | 18~22 degree | -5~5 degree |

| color type | dye and coloring | only dye |

Description of Hard Coat Anodizing production line:

1,mainly used for military parts,chiller parts,car parts etc.

2,color type:dye color

3,design method:manual/semi automatic/automatic

4,anodizing thickness: 20~50um

5,current density:2.5~4 A/dm2

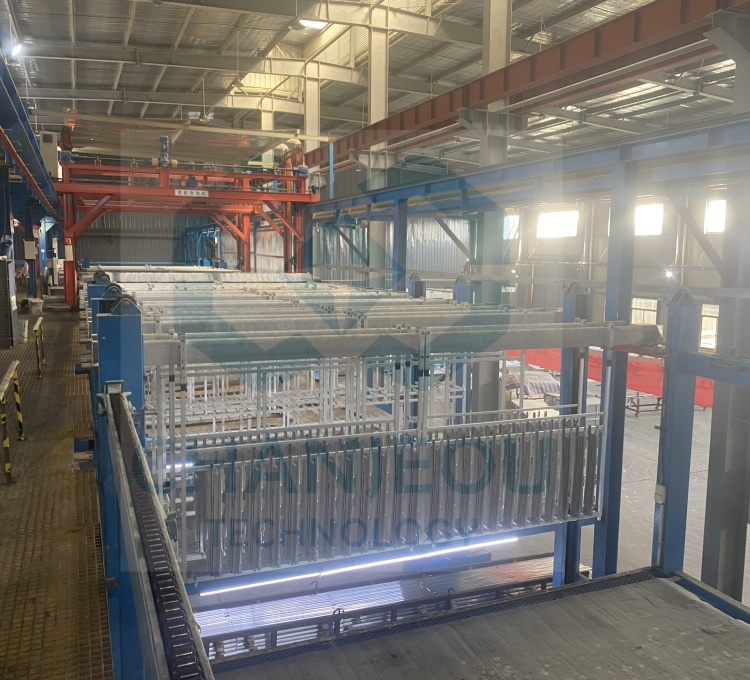

Process follow of hard coating aluminum anodizing production line:

Details introduction:

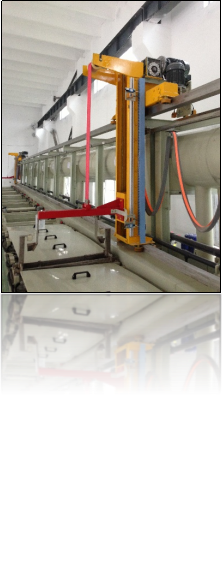

| automatic crane machine for small parts |  |

| high rail rack |  |

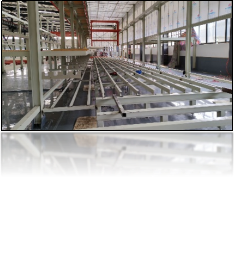

| operation platform |  |

| transport car inside workshop |  |

| PE fixing seat |  |

| Production line shielding device |  |

| anodizing rectifier |  |

| anodizing copper base |  |

| Anode beam |  |

| hoist rack |  |

| conductive system |  |

| Cathode plate |  |

| CHILLER |  |

| cooling tower |  |

| cooling pump |  |

| Temperature keeping system for pipe |  |

| filter system |  |

| Heating system for sealing tank |  |

| Circulation pipe for anodizing tank |  |

| DRY OVEN |  |

What is hard anodizing and how does it change in modern industry?

In the modern industrial field, the term 'hard anodizing' is increasingly appearing in technical documents and news reports. However, many people may still know very little about this term. This article will delve into the definition, application, advantages, and importance of hard oxidation in industry, aiming to provide readers with comprehensive and practical information to help them better understand this technology.

1. What is hard anodizing?

Hard oxidation, also known as hard aluminum oxidation, hard aluminum oxidation, or anodizing, is a technique for surface treatment of aluminum and its alloys. This technology generates a hard aluminum oxide film on the surface of aluminum through electrochemical reactions. This layer of film has extremely high hardness, wear resistance, and corrosion resistance, allowing aluminum to maintain excellent performance even in harsh environments.

What is the principle of hard oxidation?

The basic principle of hard oxidation is to use electrochemical processes to oxidize the surface of aluminum materials. The specific process is as follows:

Electrolysis process: Immerse aluminum parts into the electrolyte, use current to act as the anode, and form an electrolytic cell between the anode and cathode.

Oxidation reaction: Current passes through the electrolyte, causing an oxidation reaction on the surface of aluminum, forming an aluminum oxide film.

Film formation: Aluminum oxide film forms a thick and hard protective film on the surface of aluminum material. The thickness and properties of this film can be adjusted according to the processing time and conditions.

What are the main applications of hard oxidation?

Hard oxidation technology is widely used in multiple fields, and the following are some of the main application scenarios:

Aerospace: Due to its excellent wear resistance and corrosion resistance, aluminum materials treated with hard oxidation are widely used in aircraft components such as engine casings and fuselage structures.

Automotive manufacturing: In the automotive industry, hard oxidation is used to improve the wear resistance and corrosion resistance of automotive components, enhance the overall performance and lifespan of vehicles.

Electronic products: Hard oxidized aluminum is commonly used in electronic products for heat sinks and casings to improve durability and aesthetics.

Architectural Decoration: In the construction industry, aluminum profiles treated with hard oxidation are commonly used for door and window frames and exterior wall decoration, which are not only durable but also visually appealing.

Medical equipment: Hard oxidation technology is also applied in medical equipment to ensure durability and biocompatibility.

What are the advantages of hard oxidation?

Compared to other surface treatment techniques, hard oxidation has many unique advantages:

Excellent wear resistance: The hardness of the aluminum oxide film can reach 9-10 Mohs hardness, which makes the treated aluminum very wear-resistant and suitable for high wear environments.

Excellent corrosion resistance: The hard oxide film can effectively prevent the invasion of oxygen and moisture, thereby greatly improving the corrosion resistance of aluminum materials.

High strength: Hard oxide film not only has high hardness, but also enhances the compressive strength of aluminum and improves the stability of the structure.

Good adhesion: The bonding force between the hard oxide film and the aluminum substrate is strong and not easy to peel off, ensuring stability during long-term use.

Environmental friendliness: Compared with traditional chemical treatment methods such as chrome plating, the hard oxidation process is more environmentally friendly and does not produce harmful waste and gases.

What is the process of hard oxidation treatment?

The process of hard oxidation treatment generally includes the following steps:

Pre treatment: including cleaning, degreasing, and removing oxide layers to ensure a clean and smooth surface of the aluminum material. The commonly used methods are acid washing and alkali washing.

Oxidation treatment: Immerse the cleaned aluminum material in an electrolyte, apply electricity for oxidation reaction, and form an aluminum oxide film.

Film thickness control: The thickness and quality of the film are controlled by adjusting the current density, processing time, and electrolyte composition.

Sealing treatment: After the formation of the oxide film, it is usually necessary to perform sealing treatment to improve the corrosion resistance and wear resistance of the film. The commonly used sealing methods include hot water sealing and chemical sealing.

Post processing: Other post-processing steps such as polishing, coloring, etc. can be performed as needed to meet specific application requirements.

What are the precautions for hard oxidation treatment?

When performing hard oxidation treatment, the following points should be noted:

Choosing the appropriate electrolyte: The composition of the electrolyte has a direct impact on the quality and performance of the oxide film, and the appropriate electrolyte formula should be selected according to the requirements of the aluminum material.

Control current and time: The current density and processing time should be precisely controlled according to the requirements of the aluminum material to ensure that the film layer is uniform and achieves the expected thickness.

Keep the workpiece clean: During pre-treatment, ensure that the aluminum surface is free of oil, dust, and other pollutants to improve the adhesion and quality of the oxide film.

Environmental requirements: During the treatment process, attention should be paid to environmental protection, and the discharge of treatment liquids and waste liquids should comply with relevant environmental regulations to reduce the impact on the environment.

What is the future development trend of hard oxidation?

The future development trends include:

Technical optimization: The continuous research and development of new electrolytes and treatment processes will further enhance the performance of oxide films and meet higher application requirements.

Green environmental protection: More emphasis on environmentally friendly treatment processes will become mainstream, such as the application of chromium free treatment technology to reduce the impact on the environment.

Intelligent control: The introduction of automation and intelligent technology will improve the accuracy and efficiency of processing, and reduce labor costs.

Multifunctionality: The functions of oxide film will be more diversified, such as the introduction of conductivity, antibacterial and other functions, expanding the application scope of hard oxidation.

Hard oxidation, as an important surface treatment technology, has played a significant role in modern industry due to its outstanding performance. From aerospace to automobile manufacturing, from building decoration to medical equipment, hard oxidation technology is ubiquitous