Horizontal Powder Spaying Machine production line for aluminum profile and sheet

Brand CHANJEOU

Product origin china

Delivery time 50 days

Supply capacity 100 set per year

1. Powder spraying has Good environmental friendliness

2. Saves non renewable water resources while avoiding secondary solid waste treatment;

3. The powder can be recycled and reused to avoid paint waste;

4. High work efficiency.

powder spraying production line for aluminum profile and aluminum sheet

![]()

Powder coating Working procedure:

(18~20min)

Profile loading——►static powder painting——►powder curing——►cooling——►profile unloading

(180-220℃)

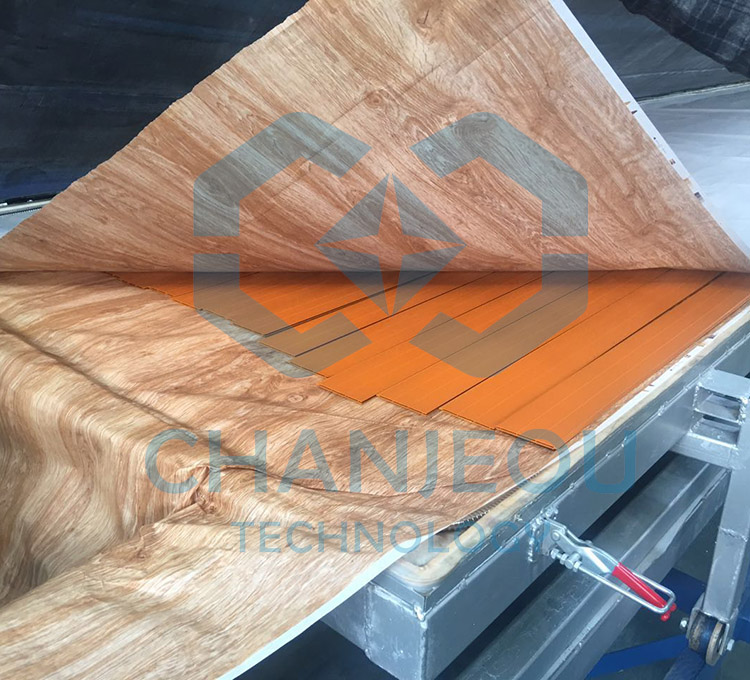

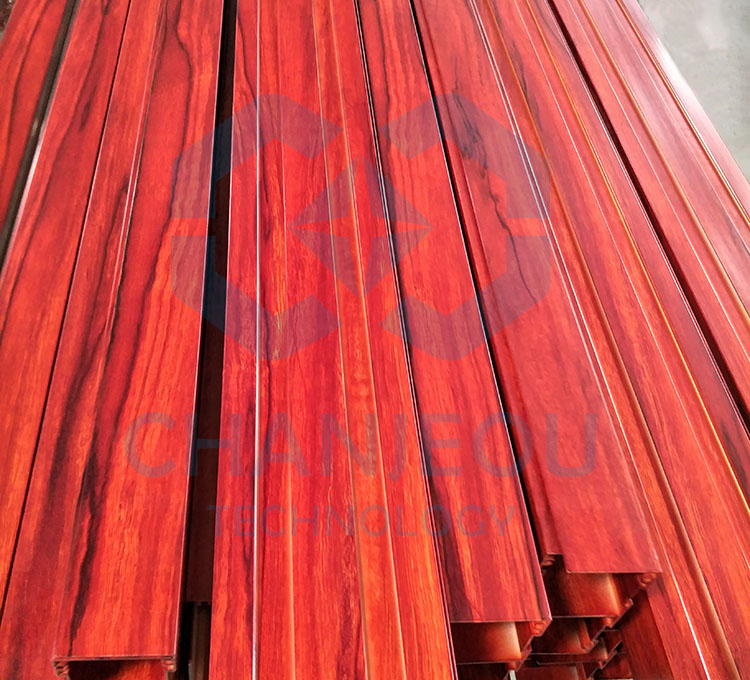

After finished do powder coating on profile. we can do wood grain sublimatioon . can do aluminum profile and aluminum sheet.

wood grain transfer machine, wood grain transfer paper with high temperature bag , heat sublimation film, film weling machine , paper cutting machine,

Powder spraying production line optional choice:

1,online spraying pre-treatment device 2,concrete pre-treatment device |

| 3,horizontal curing oven length is customized on basis of production capacity |

| 4,spraying guns quantity are customized |

| 5,spraying guns brand are optional, and customized |

| 6,design layout on basis of space size |

| 7, design capacity on basis of profile maximum length |

| 8,manual spraying room or automatic spraying room? |

The following powder spraying machine available here:

| 1, compact powder spraying machine |

| 2,vertical powder spraying machine |

| 3, horizontal powder spraying machine |

| 4,manual bakery oven |

Contact us for more information:

| Whats app:+86 13450531604 |

| Email:melody@chanjeou.com |

| Web:www.chanjeou.com |

How to choose the powder coating line?

The size selection of the horizontal spraying line for aluminum profiles should comprehensively consider factors such as spraying efficiency, material characteristics, and spraying quality. The specific size parameters include spray line length, width, and height, etc. When selecting, it should be evaluated based on actual needs and application scenarios.

Aluminum profile horizontal spraying line, as an important surface treatment equipment, is widely used in the production process of various aluminum products. The size selection of the spraying line has a significant impact on spraying efficiency, material utilization, and spraying quality. So, how should the size of the horizontal spraying line for aluminum profiles be selected? This article will provide a detailed analysis of the main dimensional parameters, influencing factors, and selection recommendations of the spray coating line.

1、 Main dimensional parameters of spraying powder coating line

The size parameters of the horizontal spraying line for aluminum profiles mainly include the length, width, and height of the spraying line. Among them, the length of the spraying line determines the continuity and production efficiency of the spraying operation; The width of the spraying line determines the spatial size of the spraying operation and the range of aluminum profile sizes that can be processed; The height of the spraying line is related to the layout of the spraying equipment and the spraying effect.

2、 Analysis of influencing factors

When selecting the size of the horizontal spraying line for aluminum profiles, the following factors need to be considered comprehensively:

1. Spraying efficiency: The length and width of the spraying line directly affect the efficiency of the spraying operation. Short length may result in discontinuous spraying operations, affecting production efficiency; If the width is insufficient, it may not be possible to handle larger aluminum profiles.

2. Material characteristics: Factors such as the material, thickness, and surface condition of aluminum profiles can also affect the size selection of the spraying line. For example, thicker aluminum profiles may require a larger spraying space to ensure spraying quality.

3. Spray quality: The height and width of the spray line have a significant impact on the spray quality. Insufficient height may limit the layout of spraying equipment and affect the spraying effect; Excessive width may result in uneven spraying operations.

3、 Selection suggestions

When selecting the size of the horizontal spraying line for aluminum profiles, it is recommended to evaluate it based on actual needs and application scenarios. Firstly, it is necessary to clarify the production efficiency of spraying operations and the requirements for the size range of aluminum profiles; Secondly, the influence of the material and surface condition of aluminum profiles on the size of the spraying line should be considered; Finally, it is necessary to comprehensively consider factors such as spray quality and equipment layout to select the most suitable spray line size.

In short, the size selection of the horizontal spraying line for aluminum profiles is a comprehensive process that needs to be evaluated based on actual needs and application scenarios. Through the introduction of this article, it is believed that readers have gained a deeper understanding of the size selection of aluminum profile spraying lines, providing useful guidance for practical applications.