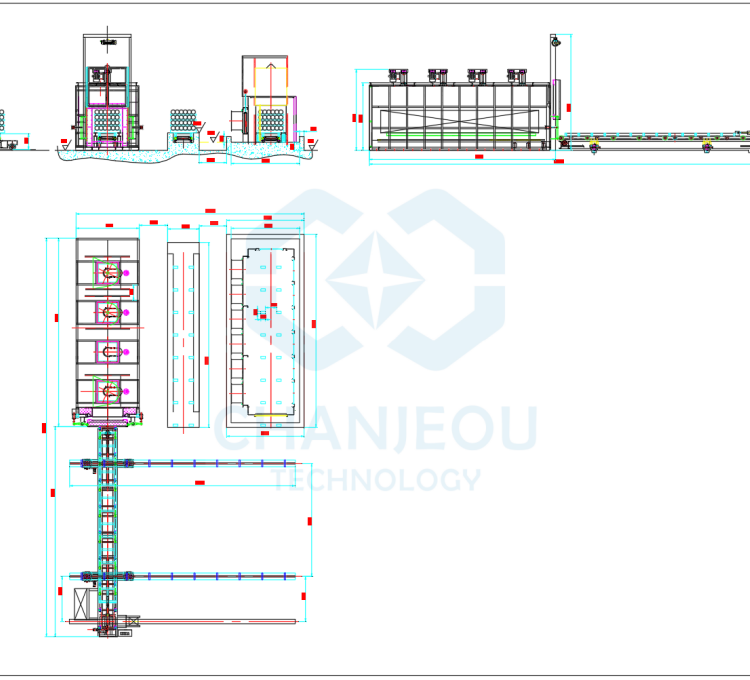

35Tons Aluminium Rod Homogenization Furnace manufacturer

Aluminium Rod Homogenization Furnace:

1,manufacturer in Foshan of China

2,35tons capacity

3,billet size is customized

4,heating fuel type is customized

Definition of Homogenization and Heterogeneity of Aluminium Rod:

Aluminum rod is a common aluminum alloy material. The organizational structure of aluminum rod refers to the distribution of aluminum and other elements in the aluminum rod, while homogeneity and heterogeneity refer to whether the distribution of aluminum and other elements in the aluminum rod is uniform. Therefore, the uniformity of organizational structure is a key factor affecting the performance of aluminum rod.

Homogenization aluminum rod refers to the uniform distribution of aluminum and other elements in the aluminum rod, with no obvious layering or impurities in the microstructure, possessing good strength and toughness. Heterogeneous aluminum rod refers to the uneven distribution of aluminum and other elements in the aluminum rod, with obvious layering and impurities, which can easily lead to defects and fragility.

2,Preparation methods for homogenization and heterogeneous aluminum rod:

The preparation method of homogenization aluminum rod usually adopts continuous casting or extrusion processes, which can effectively control the microstructure and composition distribution of aluminum bars. Heterogeneous aluminum bars are usually prepared using casting processes, and due to the uneven distribution of aluminum and other elements during the preparation process, delamination and impurities are prone to occur.

3,Scope and characteristics of application for homogenization and heterogeneous aluminum rod:

Homogeneous aluminum rods are commonly used in applications that require high strength and toughness, such as aerospace, power, transportation, and other fields. Heterogeneous aluminum bars are usually used in some low demand applications, such as furniture, construction, and other fields.

The characteristics of homogeneous aluminum bars are uniform microstructure and good strength and toughness, but the preparation cost is relatively high. The characteristic of heterogeneous aluminum bars is that the preparation cost is relatively low, it is difficult to meet the high requirements for strength and toughness.

The difference between homogenization and heterogeneous aluminum rods lies in the uniformity of their organizational structure. Homogeneous aluminum bars have better strength and toughness, making them suitable for applications that require high strength and toughness; Heterogeneous aluminum bars are suitable for applications with low requirements, but have the advantage of low preparation costs.

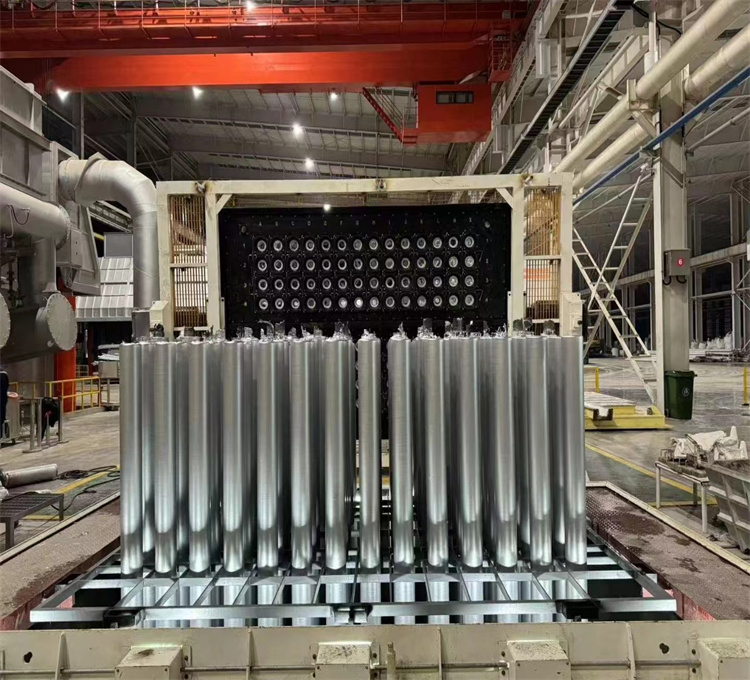

35Tons aluminium rod homogenization furnace work in India customer factory: