how to improve the tensile strength of extrusion press aluminum profile

how to improve the tensile strength of extrusion press aluminum profile?

In order to mprove the extrusion tensile strength of aluminum extrusion profile, efforts can be made from the following aspects:

1,Optimize the quality of cast billets:

reduce structural defects such as slag inclusion, looseness, and coarse grain size in the cast bars, ensuring the continuity of the cast bars

2,Reasonably control the extrusion ratio:

The extrusion ratio should be controlled between 20 and 50 to avoid insufficient metal deformation caused by a too small extrusion ratio.

3,Strengthening quenching treatment:

using strong winds to rapidly cool down aluminum profiles, ensuring quenching strength, and improving the performance and plasticity of aluminum materials.

4,Strict aging treatment:

The aging furnace should always maintain an appropriate high temperature, and the insulation time should be controlled properly to avoid affecting the tensile strength if the time is too long or too short

5,Control material composition:

The Mg2S content in 6063 aluminum alloy profiles should be controlled within the range of 0.75% to 0.80% to reduce the presence of excess magnesium or silicon, and strictly control the content of impurity elements

produce good quality of aluminum profiles, improve the extrusion aluminum tensile strength,not only rely on extrusion press machine, also need optimizing the quality of the casting billet, controlling the extrusion ratio reasonably, strengthening quenching treatment, strict aging treatment, and controlling the material composition, the tensile strength of aluminum can be effectively improved

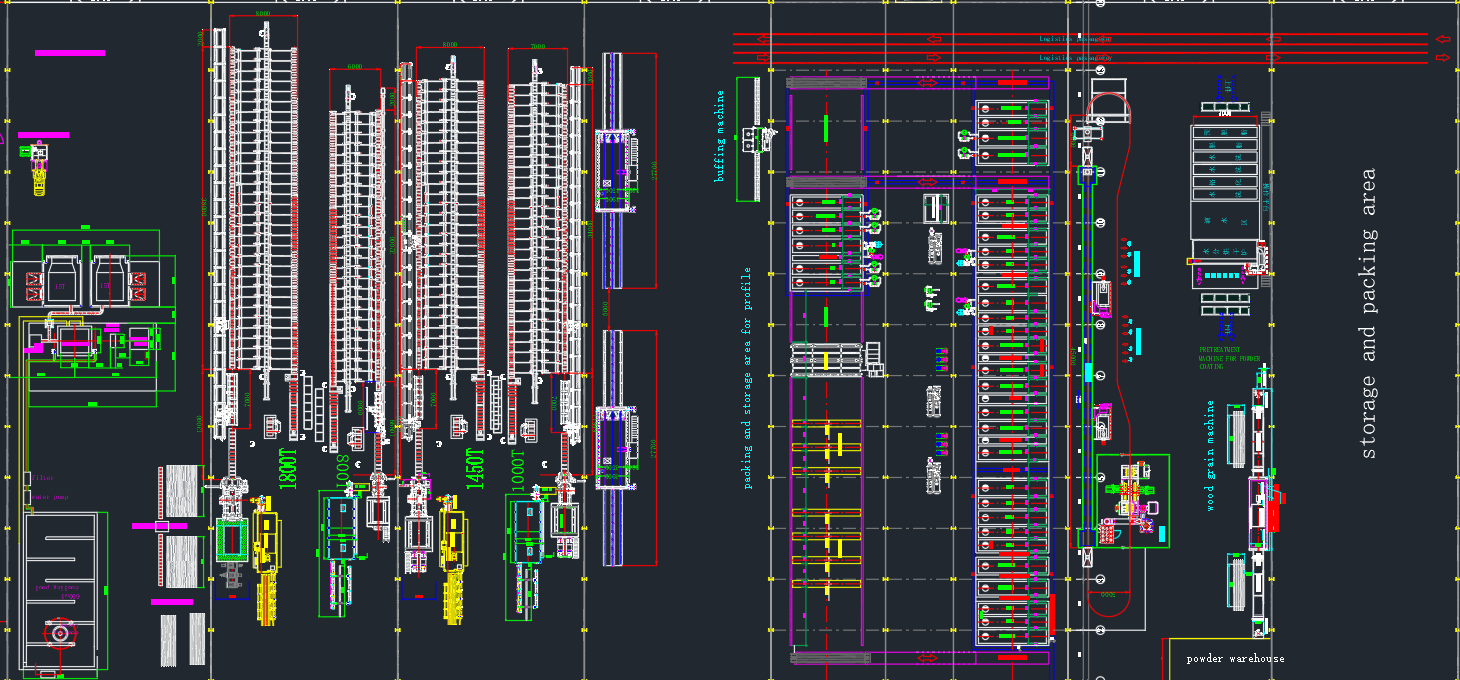

Two kinds of extrusion machine:

1,long stroke :traditinal design,strong structure,stable working,easy to maintenance and easy to operate

2,short stroke:compact design,new type design,faster speed,crane type short billet conveyer

Supply turnkey project from Aluminum profile extrusion line ,aluminum profile packing machine, aluminum profile anodizing plant, aluminum profile powder coating machine, aluminum profile wood grain sublimation machine and aluminum billet casting machine line including homogenizing furnace