Steps to use wood grain paper (with video)

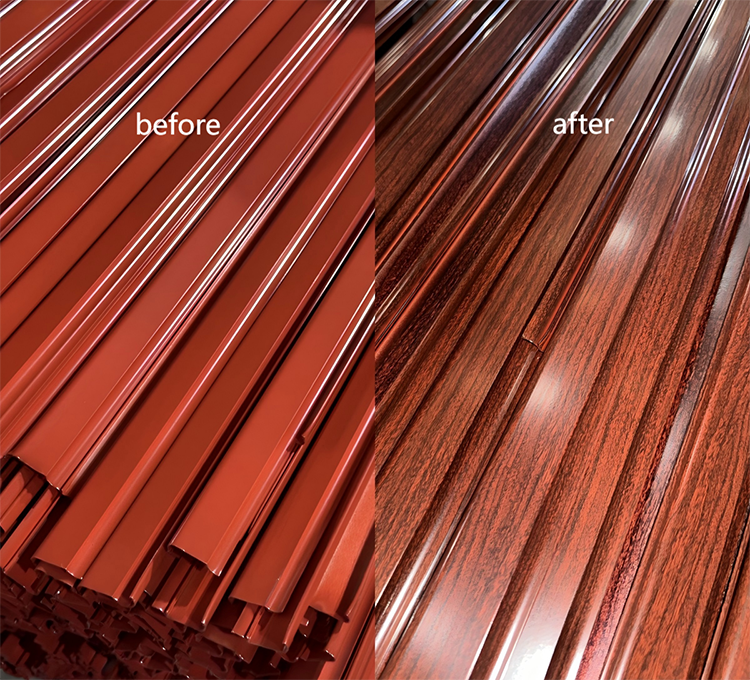

the product display of window profiles with wood grain transfer refers to the process based on electrostatic powder spraying.

according to the principle of high-temperature sublimation and thermal penetration,

the wood grain patterns on transfer paper or transfer film are quickly transferred and penetrated onto the already sprayed profiles through heating and pressurization.

this makes the produced wood grain profiles have clear textures, a strong three-dimensional effect, and can better reflect the natural feel of wood grain.

wood grain heat transfer paper/film is an ideal energy-saving and environmentally friendly material to replace traditional wood.

the wood grain has extremely strong adhesion to aluminum materials. moreover, it is non-toxic, odorless, and easy to clean. also, the product has clear and vivid patterns.

a strong three-dimensional effect, and good decorative appearance, presenting a visual effect of returning to simplicity and nature. the coating film on the surface of electrostatically sprayed aluminum profiles does not volatilize or oxidize in the air and does not cause any pollution to the environment.

and the dirt deposited on the sprayed surface can restore its original luster and appearance once cleaned.

Step 1:

Select the substrate that has already been sprayed.

Step 2:

Wrap the substrate to be transferred with wood grain heat transfer paper, and fix the interface of the paper with high-temperature-resistant adhesive tape to prevent the wood grain heat transfer paper from loosening.

(Note: The front side of the wood grain heat transfer paper should be attached face to face with the surface of the substrate to be transferred.)

Step 3:

Then put a tubular high temperture plastic bag with high temperature resistance and good sealing performance over the substrate wrapped by the wood grain heat transfer paper.

After that, vacuumize from both ends of the plastic bag until the plastic bag can fully and effectively cling to the substrate.

The negative pressure of the vacuum should be adjusted appropriately according to the characteristics of the substrate to be transferred and the negative pressure that the high Temperture plastic bag can withstand.

It is usually between 0.3 and 0.8 Mpa. (Note: The purpose of using the high temperture plastic bag is to force the wood grain heat transfer paper to fully and effectively cling to the substrate through the negative pressure of the high temperture plastic bag that is already closely attached to the substrate.)

Step 4:

Send the wrapped substrate to the wood grain heat transfer furnace. The transfer temperature and transfer time should be adjusted appropriately according to comprehensive factors such as the characteristics of the substrate to be transferred, the depth of the texture to be transferred, and the specific performance of the oven. Usually, the transfer temperature is 160 - 180 °C, and the time is 5 - 8 minutes.

Step 5:

Take out the transferred substrate from the furnace, pull off the plastic bag from one end of the transferred substrate , tear off the heat transfer paper, and conduct surface cleaning.

Step 1:

Select the substrate that has already been electrostatically sprayed.

Step 2:

Lay the front side of the wood grain heat transfer paper flat against the front side of the substrate to be transferred.

Step 3:

Use a flat plate heat transfer machine for pressurization and heating. Usually, the transfer temperature is 160 - 180 °C, and the time is 18 - 25 seconds.

Step 4:

Tear off the heat transfer paper and use the PET heat transfer film for transfer.