Aluminum profile anodizing&electroplating pneumatic and manual clamps

How to choose the anodizing clamp electroplating clamp?

1, manual clamp

2,pneumatic clamp

3,anodizing clamp

4,electroplating clamp

Many customer said their clamp is not suitable use, let us explain how to choose the anodizing clamp and electroplating clamp:

1,pneumatic clamp is higher efficiency ,but not suitable for every kind of profile ,some profile must need manual profile

why some aluminum profile must need manual clamp?

such as kitchen type aluminum profile, clamp hole is very small, so must need small size manual clamp.

2,anodizing clamp can not used in electroplating clamp, but electroplating clamp can use in anodizing

3,for acide treatment ,such as Nitric,Phosphoric,Sulphuric treatment, the pump is special not same with regular aluminum profile clamp

4,color of aluminum profile clamp can be yellow, white,green and black.

Contact us freely, help you to choose the best suitable anodizing clamp and electroplating clamp:

| email:melody@chanjeou.com |

| whats app:0086 13450531604 |

Pneumatic clamp operation video:

How to judge the aluminum profile clamp durability(manual clamp and pneumatic clamp):

1,Visual inspection: Observe the surface changes of the anodizing clamp in high-temperature environment. If there are no cracks, deformations, or other damages on the surface of clamp, it indicates that anodizing clamp heat resistance is good

2,Resistance test: Use a multimeter to measure the resistance of the clamp. The presence of anodizing film increases resistance, while the resistance of unoxidized parts is lower. By comparing the resistance values at different temperatures, the heat resistance performance of the clamps can be evaluated.

3,Scratch test: Use a needle or other hard object to gently scratch the surface of the clamp and observe for any scratches. The surface that has formed a good anodizing film should not be easily scratched, indicating its good heat resistance

4,Coloring test: immerse the clamp in a specific staining solution and observe its coloring condition. The anodizing parts will quickly color, while the unoxidized parts will not. This method can effectively distinguish between oxidized and non oxidized areas

5,Chemical analysis: Use chemical reagents to treat the surface of the clip and analyze the composition of the oxide film. EDS (Energy Dispersive X-ray Spectroscopy) and other techniques can be used for in-depth analysis

6,Heat resistance standard for aluminum profile clamp(manual anodizing or pneumatic clamp):

Heat resistance: Anodized film can withstand high temperatures of about 1500 ℃, while pure aluminum can only withstand 660 ℃. In sulfuric acid electrolyte, the oxide film will not crack even at 130 ℃, and its heat resistance can reach 150 ℃ or even higher

7,Thermal stability: The oxide film has high thermal stability and can maintain its performance and structural integrity in high temperature environments

Manual clamp photo:manual clamp need more man work,but suitable for to many kinds of aluminum profile

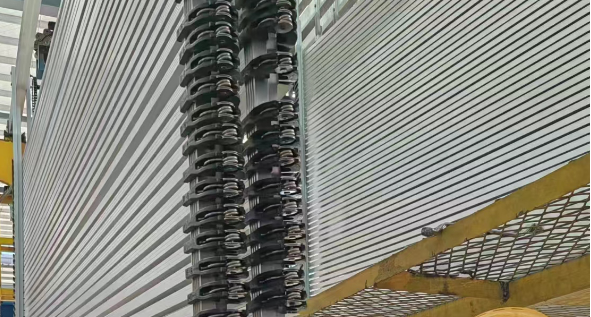

Pneumatic clamp photo:

Contact us for manual clamp,pneuamtic clamp,aluminum profile clamp freely