Deliver 45kw extrusion mould nitriding furnace machine and compressed air machine to Bangladesh

Deliver 45kw Extrusion mould nitriding furnace machine to Bangladesh,another two sets of 45kw nitridng furnace machine are ready to deliver to India. catch customer on basis of good price of value, good after sales service.

Many customer ask us how to put the extrusion mould inside of extrusion nitriding furnace, here is the photo:

you can put as you want, just consider more loading in same basket size, it will not affect the mould function.

How to choose the size of extrusion mould nitriding furnace machine?

1, check loading capacity per day

2, check extrusion mould size

3, basket size of each size of extrusion nitriding furnace as follows:

| machine size | 30kw | 45kw | 60kw | 75kw | 90kw |

| basket size | Dia.450*650mm | Dia.550*1000mm | Dia.650*1200mm | Dia.800*1200mm | Dia.800*1800mm |

How to storage the ammonia gas?

Answer:in our factory, you see big cylinder of liquid ammonia, because in China, have strict policy about ammonia gas storage, so we make isolate room with ventilation, but without air-conditioner, question: when Indian weather temperature is high, need air-conditioner?

Answer:no need air conditioner, if too low temperature for ammonia, the ammonia can not run smoothly, need use water to warm it let ammonia run smoothly.

How to operate extrusion mould nitriding furnace?

Answer:Nitriding furnace is controlled by Siemens PLC and operation by HMI. Can operate by manual and automatic.

In our program, already set all the operation procedure, after open compressed air,cooling water, open automatic operation switch, then it work automatically.

when open the ammonia for extrusion nitriding furnace machine?

Answer:In our program, already set when temperature reach 350 degree, the ammonia will automatically open

when cooling the extrusion die, the extrusion nitriding furnace machine's door open or close?

Answer:When cooling the extrusion die, the furnace door is closed.

Use cooling fan to cool the extrusion die(inside nitriding furance, already have cooling fan),In our PLC program, when temperature reach 120 degree,can take out the extrusion die.

After extrusion nitriding furance machine, which hardness of extrusion die can reach?

Answer:It is 950~1200HV

How to test the hardness of nitriding?

Answer:there is special tools to test

How many electricity consumption for extrusion mould nitriding furnace machine?

Answer:130~140kw.h/furnace

Why our electricity consumption of extrusion nitriding furance machine is lower than others?

Answer:Our nitriding furnace structure:

(1),Compare brick and rock wool :

1,rock wool is more better for energy saving

2,rock wool let temperature cool faster

3,rock wool is more longer use ,brick have chance to break ,but rock wool never break and change

Right now our bottom also use full cotton, no brick, so energy consumption is more lower

(2)The structure of side wall

1,ourside is Q235 carbon steel plate ,4mm thickness

2,then thermal insulation rock wool and heating elements

3, then 5mm thickness SUS 321 plate

4,then extrusion die baskets (SS 304)

(3)The structure of furnace cover :

1,outside is Q235 carbon plate ,4mm

2, then thermal insulation rock wool

3, then SUS 321 plate ,5mm thickness

On furnace cover ,there is Mixing fan ,for circulation temperature and ammonia gas ,make sure temperature uniform

The pump is anti corrosion and explosion proof pump

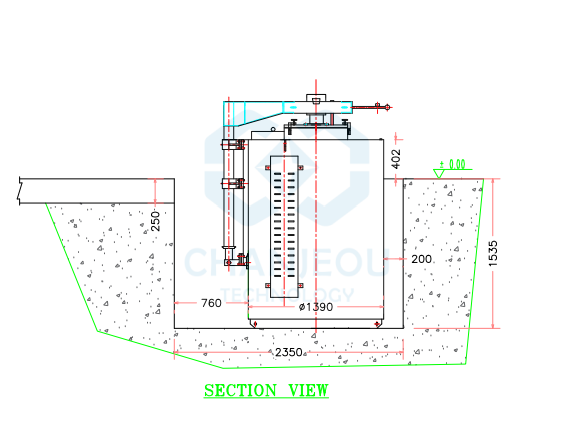

How many space need for extrusion mould nitriding furnace machine?

Answer:please check drawing